News

Pulp

Resolute’s Calhoun upgrade will handle hardwood and softwood pulp

August 27, 2014 By Pulp & Paper Canada

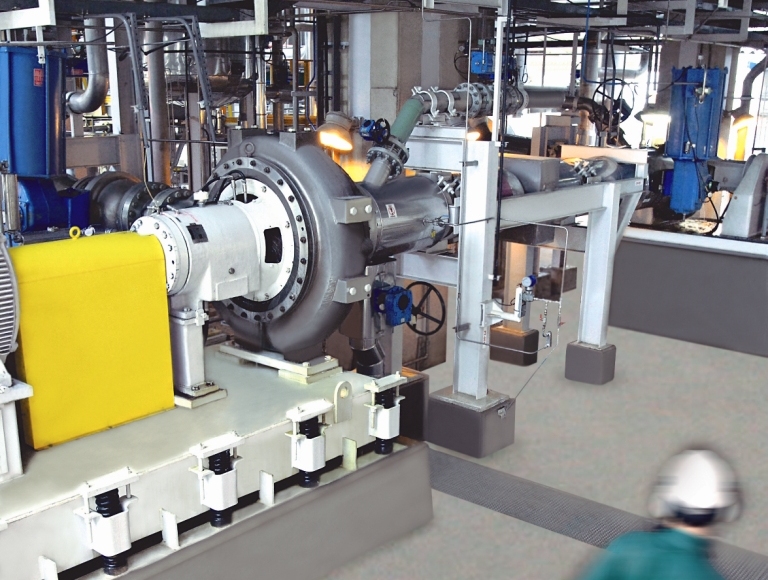

Resolute has chosen the Andritz TurboFeed chip feeding system for the upgrade at the Calhoun mill. TurboFeed's layout flexibility is said to be well suited for modernizations.

Resolute has chosen the Andritz TurboFeed chip feeding system for the upgrade at the Calhoun mill. TurboFeed's layout flexibility is said to be well suited for modernizations. Resolute Forest Products broke ground on a US$105-million upgrade project at its Calhoun, TN, pulp and paper mill on Aug. 19. The project includes a continuous cooking system and additional fibreline equipment from Andritz.

Resolute Forest Products broke ground on a US$105-million upgrade project at its Calhoun, TN, pulp and paper mill on Aug. 19. The project includes a continuous cooking system and additional fibreline equipment from Andritz.

According to Resolute, the new digester replaces eight older ones, and will help the mill produce more pulp at higher quality. The Lo-Solids digester from Andritz will be designed to switch between hardwood and softwood pulp production, producing 1,400 ADST of bleachable softwood and 1,659 ADST of bleachable hardwood pulp per day.

When the investment was announced in March, Resolute president and CEO Richard Garneau said: “This investment will make a good mill even better. It will improve the mill’s long-term competitiveness by lowering its costs and giving it the flexibility to adjust grade production to changing market dynamics.”

Andritz will supply equipment, engineering, and field services for a new Lo-Solids continuous digester including Andritz’s patented TurboFeed chip feeding system, which will replace an existing displacement batch pulping process. Start-up is scheduled for the third quarter of 2015.

Andritz will also supply a blowline pressure diffuser and will upgrade the mill’s oxygen delignification and bleaching systems. In terms of automation, the order also includes advanced process control and IDEAS dynamic simulation software.

The upgrade is also expected to has a positive impact on the mill’s environmental performance, particularly in the area of its discharge. According to Resolute, the mill’s measurable environmental impact will be 30% less to the receiving stream once the new continuous pulp digester comes on line.

Print this page