Products

Packaging

Paper

Test & Measurement

Tissue

ABB launches virtual online measurement for weight

November 27, 2020 By P&PC Staff

ABB's Weight Virtual Measurement solution. Photo: ABB

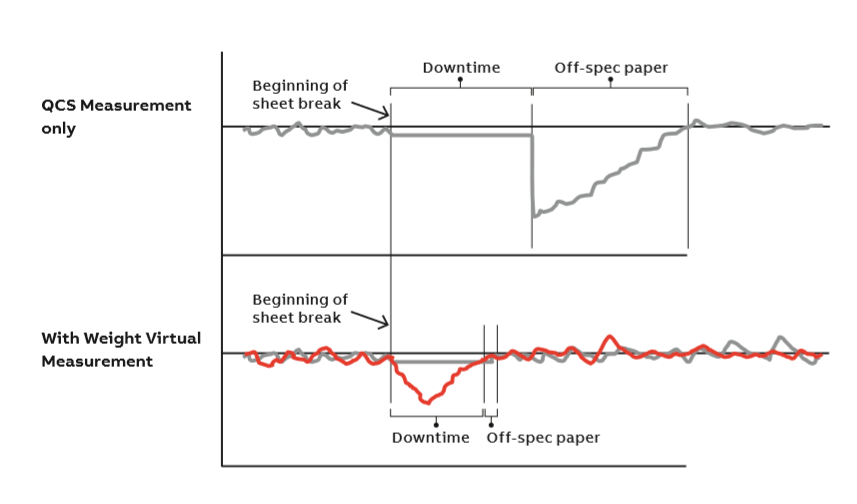

ABB's Weight Virtual Measurement solution. Photo: ABB ABB has launched Weight Virtual Measurement, a service that allows paper, packaging and tissue manufacturers to recover quickly from sheet breaks.

The new digital solution uses inputs that affect product weight – such as stock flow, consistency, first pass retention and machine speed – to provide an online conditioned weight measurement during a sheet break event when the quality control system (QCS) weight sensor cannot provide a measurement since there is no paper to be measured.

By providing operators with a continuously optimized, machine-learning generated measurement model, or “soft sensor,” Weight Virtual Measurement can help to reduce downtime, improve grade change times and decrease the time to achieve on-spec paper.

Operator displays combine various inputs and highlight when the virtual measurement is available in the absence of the QCS measurement. Operators can view the current status and work with a choice of adjustments to get back on target.

Weight Virtual Measurement joins the ABB Ability Performance Service suite that includes other virtual measurement features for pulp and paper mills, all of which do not require an ABB DCS or QCS for implementation.

It is delivered via ABB Ability Collaborative Operations, a service delivery model that connects production, headquarters and ABB personnel with remote access to ABB digital technologies, data analytics and domain expertise, and incorporates ongoing performance monitoring and analysis of the online calculated weight.

Print this page