Features

Bioeconomy

Paper

Pulp

Research & Innovation

Bacterial nanocellulose tested as strength enhancer

May 2, 2018 – A new research project has been launched to test bacterial nanocellulose (BNC) as a potential strength enhancer in board, textiles and bioplastics.

May 2, 2018 By P&PC staff

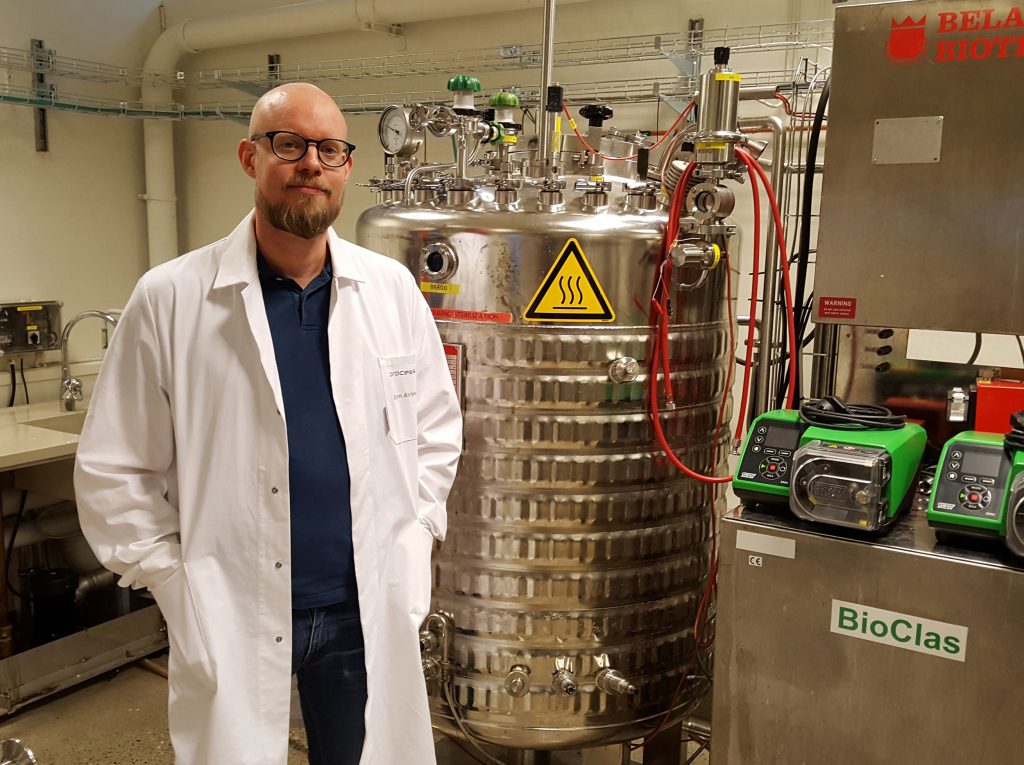

Björn Alriksson

Björn Alriksson The project is being jointly undertaken by Umeå University and Processum to develop methods for the production of BNC from residual streams from the pulp and paper industry. Both parties welcome collaboration from the pulp and paper industry as well as from companies on the application side.

Different types of nanocellulose can provide new and improved characteristics to several different materials. Research and most demonstration and production efforts has so far been focused mainly on cellulose nanofibres (CNF) and cellulose nanocrystals (CNC). Umeå University and Processum researchers will develop and scale up a method for production of BNC which is nonocellulose produced by bacteria.

“At Umeå University, our research group has already been able to produce bacterial nanocellulose in laboratory scale based on residual streams from a pulp mill,” Professor Leif Jonsson, in charge of the research group, said. “We have produced small amounts of BNC which we have added to paper with promising results. The paper got improved mechanical characteristics, i.e. higher tensile and tear index. Nanocellulose produced with the aid of bacteria differs from CNF and CNC. It is purer, has a higher degree of polymerisation, is more cystalline and thinner.”

Bjorn Alriksson, head of group, biotechnology, at Processum, said today’s method of producing bacterial nanocellulose is expensive, methods are inefficient and the growth medium is expensive.

“This is why we will use low-value residual streams from pulp mills as substrate, and the production will be carried out in stirred bioreactors to try to improve the production,” he said. “In this project, we will scale up the process starting in our laboratory scale multibioreactors, then continue with experiments in our 50-litre bioreactor, and finally we will will produce BNC in a 600-litre reactor.”

The BNC will be tested in applications such as strength enhancer in board, textiles and plastics. The goal is to produce BNC from industrial residual streams for applications where relatively high volumes of BNC are needed.

“Nanocellulose research has for years been a strong area within RISE,” Pernilla Walkenstrom, acting division manager, RISE Bioeconomy, said. “The cooperation between Processum and Umeå University really complements the research activities done on MFC/NFC and CNC.”

Jonsson and Alriksson said BNC is an interesting product that can give improved charactisterics to existing materials and can also be used for the production of entirely new bio-based materials. They said they hope to have enough BNC for realistic application tests by the end of the project, and are open to national and international cooperation in different fields for a joint development of applications.

Print this page