Features

Bioeconomy

Energy Management

Environment & Sustainability

Biofuels demand in 2050: An opportunity for the Canadian forest sector?

June 21, 2022 By Tom Browne

Photo: Annex Business Media

Photo: Annex Business Media Carbon dioxide emissions arising from energy use represented about 73% of world greenhouse gas (GHG) emissions in 2016[1], with land, air and marine transportation representing 16.2%. With some exceptions, decarbonizing land-based transportation can largely be accomplished through electrification, but long-haul aviation, and to a lesser degree off-road and marine uses, will continue to require liquid fuels with high energy densities. Biofuels will play an important role in these applications.

Typically, forest-based biofuels are not economic unless climate-related costs are factored into the price of the fossil-based competitor at the pump. For example, a carbon tax of $50 per tonne of carbon dioxide equivalent (tCO2EQ) adds about $21 to the price of a barrel.

Given the worldwide focus on climate change and the related need for new energy products, what biofuels products will be needed in 2050? Can they be provided in reasonable volumes by the Canadian forest sector? And what “effective oil price” is necessary to make them economically viable? This note attempts to address the first two.

The International Energy Agency (IEA) has published a roadmap for reducing greenhouse gas (GHG) emissions due to energy use. This so-called Net Zero by 2050 (NZE)[2] scenario includes a mix of energy substitution and efficiency approaches, supplemented by carbon capture, use and storage (CCUS). This scenario projects world fossil fuel use for transportation declining from 111 EJ (1 EJ = 1018 Joules or 109 GJ) in 2020 to 9 EJ in 2050. Over the same period, world biofuel demand is projected to increase from 4 EJ to 16 EJ[3].

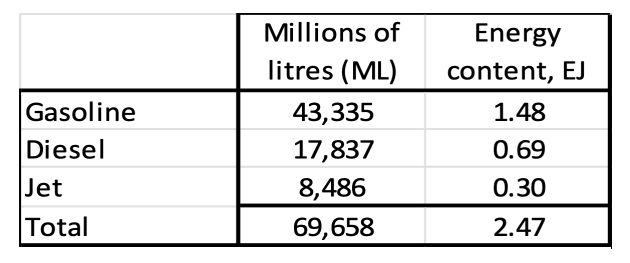

According to Statistics Canada, Canadian sales of major transportation fuels (gasoline, diesel[4] and aviation jet fuel[5]) totalled 69.7 billion litres in 2019 (Table 1). Converting to energy units gives a total of 2.47 EJ or about 2.2 percent of current world demand.

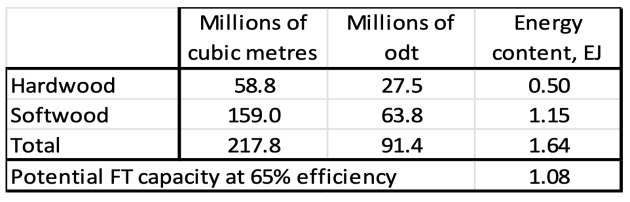

The Canadian Council of Forest Ministers (CCFM) provides data on Canadian industrial wood supply and harvesting volumes[6]. Table 2 shows industrial wood supply and estimates of total oven-dried weight, assuming freshly harvested wood consists of 50 percent water. The total energy content of the 2019 Canadian wood supply works out to 1.64 EJ.

Table 1: 2019 Canadian transportation fuel sales. Source: StatsCan.

Table 2: 2019 Canadian sustainable wood supply. Source: CCFM.

The Fischer-Tropsch (FT) process gasifies biomass to carbon monoxide and hydrogen, then synthesizes a hydrocarbon stream suitable for processing in a conventional petroleum refinery. The synthesis stage can be designed to yield methane or a more complex hydrocarbon. Energy yield is typically of the order of 65 percent, meaning that for every GJ energy content in the feed, about 0.65 GJ of fuel is produced. At that rate, the total Canadian industrial wood supply, converted to transportation fuels, would yield 1.08 EJ of liquid transportation biofuels. This is less than half of the current Canadian demand, although it would be sufficient to meet the combined Canadian demand for diesel and jet fuel.

The NZE predicts 16 EJ world demand for liquid biofuels in 2050, up from 4 EJ today. Canada’s domestic fuel share of 2.2 percent, assumed constant to 2050, is 0.035 EJ, requiring about a third of the 2019 wood supply. While still large, it is possible to imagine Canadian biofuels producers meeting a substantial portion of domestic 2050 demand by converting residual material not used for other products.

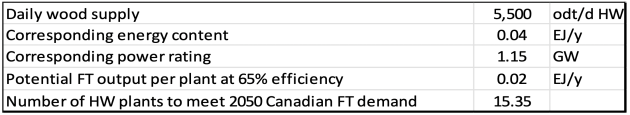

Canada’s largest pulp mills consume wood at a rate of about 5500 odt/d. This upper limit is largely due to costs associated with larger haul distances as mills need additional tonnes. Hardwood grows back faster, so softwood mills tend to be smaller as the haul distances are longer. Table 3 shows that a hardwood mill at this scale corresponds to a rate of energy use of 1.15 GW. Canada’s entire biofuels demand in 2050 could be met with about 16 GW-scale FT plants running on hardwood, or 20 to 25 softwood-fed 0.80 GW scale plants each consuming 3750 odt/d.

Table 3: Typical large-scale Canadian hardwood pulp mill wood consumption and corresponding potential FT output.

This thought experiment is obviously unrealistic, as it assumes all other uses of wood are discontinued in favour of biofuels. But it serves to illustrate the scale of the global problem, as well as the potential opportunity for large-scale new product development in the forest sector by 2050. The first step will be identifying the long-term availability of underutilized timber, thinnings, roadside slash, sawdust, bark and chips, in terms of volumes, quality and delivered costs.

An operating pulp or paper mill is the obvious locale for a new plant, due to the availability of wood and chip handling systems, boilers and steam systems, on-site power generation and grid connections, and effluent treatment plants. As well, pulp and paper mills tend to be close to the biomass; a forest biorefinery adjoining a petroleum refinery only makes sense where the refinery also adjoins significant biomass supplies, as is the case with UPM’s new biorefinery[7] in Leuna, Germany.

There are significant technology risks. Many woods to biofuels technologies, such as fermentation, use only the cellulose portion of the feed; one must then find a market for the lignin. The Fischer-Tropsch process converts the entire feed into a fuel, thus increasing yield, but currently no such plant exists operating on wood residues at a commercial scale. The best publicly available information on biomass-based FT processes comes from the GoBiGas project[8], [9] in Gothenburg, Sweden, which aimed to provide renewable natural gas from bark to the city’s gas distribution network. The economics were challenging, even with the willingness of Swedish governments to pay well over market rates for non-fossil fuels; the 20 MW pilot was mothballed and a proposed 200 MW scaleup was shelved.

Adequate and consistent government action over the next 30 years will be needed to make biofuels competitive with fossil fuels. A variety of policy levers exist, such as renewable fuel standards, carbon taxes and capital support of various kinds for first-of-kind plants. The growing world-wide consensus that climate change is an existential challenge facing humanity means the conditions may well be right for these pathways. The large number of Sustainable Aviation Fuel (SAF) announcements in recent months, such as the one by Gevo and ADM[10], supports this conclusion.

While risks remain, the world is showing signs of recognising the true costs of climate change, such as floods, heat waves, forest fires and drought. These costs are not covered by the price of fuel at the pumps. The result could be reduced risks for projects to convert biofuels from forest sources. Stay tuned!

Tom Browne is the principal at Tom Browne & Associates.

References

[1] https://ourworldindata.org/emissions-by-sector, viewed 2022-04-01.

[2] “Net Zero by 2050: A Roadmap for the Global Energy Sector”, International Energy Agency, 2021, Paris, https://www.iea.org/reports/net-zero-by-2050, viewed 2022-02-28.

[3] Net Zero by 2050, Table A.2, page 197.

[4] Statscan Table 23-10-0066-01, https://www150.statcan.gc.ca/t1/tbl1/en/tv.action?pid=2310006601, viewed 2022-04-27.

[5] Statscan Table 23-10-0267-01, https://www150.statcan.gc.ca/t1/tbl1/en/tv.action?pid=2310026701, viewed 2022-04-27.

[6] http://nfdp.ccfm.org/en/data/woodsupply.php, viewed 2022-04-27.

[7] https://www.upmbiochemicals.com/about-upm-biochemicals/biorefinery-leuna/, viewed 2022-06-08. See also https://bio-economy-tbrowne.blogspot.com/2022/04/the-forest-biorefinery-update-in-era-of.html.

[8] Larsson, A., Gunnarsson, I, and Tengberg, F., “The GoBiGas Project: Demonstration of the production of biomethane from biomass via gasification”, Göteborg Energi.

[9] Thunman, H. (ed.), “GoBiGas demonstration – a vital step for a large-scale transition from fossil fuels to advanced biofuels and electrofuels”, ISBN 978-91-88041-15-9.

[10] https://gevo.com/products/ethanol/gevo-and-adm-saf-through-ethanol/, viewed 2022-04-27.

Print this page