Features

Equipment & Systems

Maintenance & Reliability

Boiler optimization: Lower GHG emissions, increase profit

A novel approach to reducing natural gas consumption, maximizing use of biomass as a fuel and reducing emissions

July 21, 2021 By FPInnovations

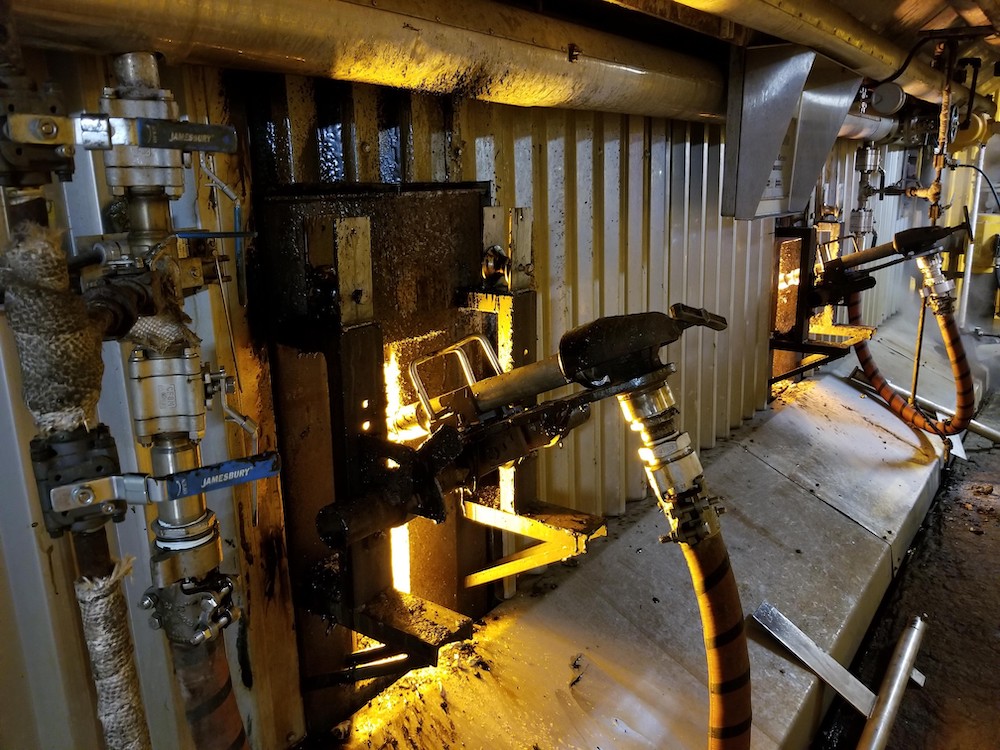

Liquor nozzles on a recovery boiler. Photo: FPInnovations

Liquor nozzles on a recovery boiler. Photo: FPInnovations Mills are constantly looking for ways to increase profitability while decreasing their greenhouse gas (GHG) emissions.

The advent of the new federal carbon tax offers new opportunities for forest sector companies to do both by optimizing the operations of their biomass and chemical recovery boilers.

FPInnovations’ approach to reducing natural gas consumption, to maximizing use of biomass as a fuel, and to reducing emissions is well-proven and has been demonstrated at many mills across Canada.

Room for improvement? Always!

Biomass and chemical recovery boilers are a large, once-or-twice in a lifetime, capital investment for a mill. Consequently, most of the boilers in Canada have been in service for many decades. Just like an old sports car, they require regular tuning and maintenance to ensure optimal performance.

FPInnovations’ boiler optimization service can maximize efficient and sustainable operation of boilers, leading to significant savings as well as an important reduction of GHG emissions.

Two decades ago, FPInnovations developed and patented an approach to boiler optimization that has been further improved and developed over the years. The approach employs unique software and measurement tools as well as a set of proven guidelines that take into consideration each mill’s specific situation and needs.

Depending on whether the target is a recovery boiler or a biomass boiler, optimizing a boiler’s performance can:

- Increase revenue by over $2.5 million US per year in additional pulp production for a 1,000 tpd kraft mill

- Reduce boiler shutdowns for water washing, which translates to savings of $0.5 – $2.5 million US per year

- Reduce natural gas consumption by $1 – $3 million US per year

- Better control TRS, particulate and other air emissions

- Improve energy efficiency, and hence contribute to the reduction of overall carbon emissions

And the cherry on top? Boiler operations can be improved with small or no capital investment.

How is a boiler optimized?

The approach is slightly different depending on whether the boiler is a biomass boiler or a chemical recovery boiler. However, the first step in both cases is to benchmark the boiler design and operational data to identify possible issues and, therefore, opportunities for improvement.

FPInnovations then conducts mill visits and performs baseline evaluation and optimization trials involving measurement, monitoring and analysis:

- Combustion air temperature, pressure, flowrate and vertical splits

- Combustion air flow distribution

- Char bed and furnace temperature profiles using handheld infrared and/or fibre-optical pyrometers

- Carryover measurements around the bullnose level

- Liquor analyses, liquor firing parameters and liquor gun and spraying nozzle setup

- Ash sampling and analyses

- Flue gas emission monitoring

FPInnovations’ expert performing combustion air mapping on a recovery boiler for troubleshooting. Photo: FPInnovations

Issues and opportunities identified are then discussed with mill staff, and decisions are made to adjust boiler operation. Adjustments include how the fuel (black liquor or biomass) is distributed as it enters the boiler.

Similarly, the split of combustion air entering the boiler at different levels, as well as around the circumference of the boiler, is carefully balanced to enhance mixing and reduce the chimney effect in the upper furnace.

Multiple rounds of measurements and monitoring are conducted to ensure that the process is fully optimized and to confirm the improvement of boiler operation. The end result: a well-tuned boiler that can efficiently burn more biomass or black liquor, use less natural gas, and reduce air emissions and carbon footprint.

_____

FPInnovations is a not-for-profit organization that supports the Canadian forest sector’s global competitiveness. For more information, please contact Wenli Duo, lead scientist at FPInnovations, at wenli.duo@fpinnovations.ca or Stéphan Larivière, pulp and paper industry sector leader at stephan.lariviere@fpinnovations.ca.

This article appears in the Summer 2021 issue of Pulp & Paper Canada.

Print this page