Features

Bioeconomy

Paper

Pulp

Creating value with lignin through research and innovation

Ongoing research and development in Canada is enabling the creation of higher value products with lignin.

October 25, 2021 By J. David McDonald

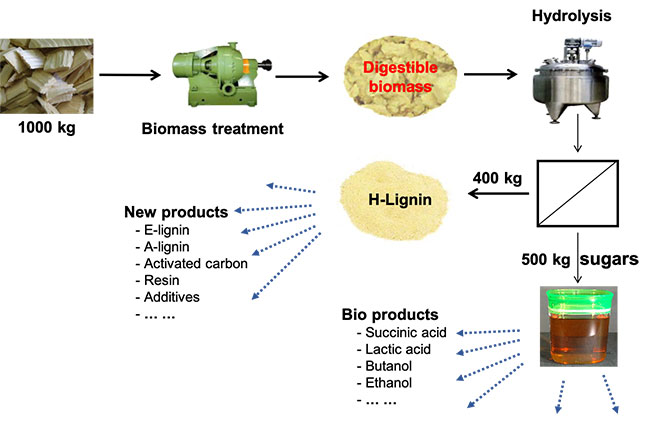

The figure shows the TMP-Bio process flowsheet.

Images: FPInnovations

The figure shows the TMP-Bio process flowsheet.

Images: FPInnovations

The Canadian forest industry could be more profitable and resilient to market swings by making a wider variety of products of higher value. Products from lignin offer that possibility. Lignin is the second most abundant biopolymer next to cellulose and represents 30 percent of all the non-fossil organic carbon on Earth. It is concentrated in the cell walls of wood and acts as a stiffening agent and a hydrophobic lining to permit water transport in trees. The largest commercial source of lignin is a by-product of the sulphite process. However, applications of lignosulphonates are limited to lower-value products. Additionally, sulphite pulp production has been diminishing over time because of reduced pulp strength properties and environmental concerns.

Alternative processes and applications

Over the past 15 years, FPInnovations has made significant progress in developing alternative commercial processes that can extract lignin from wood. It helped develop LignoForce, a process to separate lignin from kraft black liquor. This process was implemented in a 30t/day plant that was installed in West Fraser’s Hinton pulp mill in 2016. FPInnovations’s patented TMP-Bio technology utilizes wood chip refining and enzymes to produce separate lignin and sugar streams. A 100 t/year demonstration plant was installed in Resolute’s Thunder Bay mill in 2019. These developments have been coupled with an extensive research program at FPInnovations to identify novel product applications for these unique lignins.

Another effort in this direction is the LignoWorks Canada-wide university research network (2009-2016). This network was initiated by John Kadla of the University of British Columbia to better understand the fundamental nature of lignin and to discover future high-value applications such as carbon fibres, composites and pharmaceuticals. This network was unique in that it attracted researchers with experience in other industries such as petrochemicals, food processing, advanced materials and pharmaceuticals to apply their expertise with other chemicals and polymers to processing lignin.

Roughly, a tree is composed of 50 percent cellulose, 25 percent lignin and 25 percent hemicellulose. Chemical pulping is designed to separate valuable cellulose fibres from lignin and hemicellulose which are contained in the black liquor. Since the early 1930s, with the invention of the recovery furnace in Canada by Tomlinson, the black liquor has been burned to recover pulping chemicals and generate energy in the form of steam for internal mill use or for powering turbines for electricity generation. However, for over a century, chemists have recognized that the complex, aromatic structure of the lignin molecule contains the building blocks of many valuable chemicals. Early product inventions using lignin by Tomlinson include the decorative laminate Arborite (Howard Smith Paper Company later acquired by Domtar) and vanillin, implemented at the Howard Smith mill in Cornwall and the Ontario Paper Company mill in Thorold.

Lignin is composed of many different phenols (hydroxyl -OH group attached to an aromatic ring) which makes it like a giant Lego set where only the imagination limits what can be constructed. So, chemists have dreamed about how they might cleave, depolymerize or fractionate lignin to make a variety of high-value products. But the range of products that can be made from lignin, and their value, depend on the process used to extract and purify the lignin.

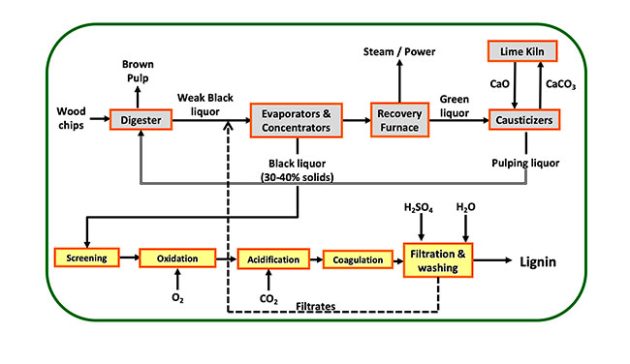

Shown here is the LignoForce System flowsheet.

LignoForce

The LignoForce process was developed by FPInnovations and is marketed by NORAM Engineering & Constructors. This system was first demonstrated at the Resolute mill in Thunder Bay, Ont., at the 50 ODkg/d scale and subsequently adopted by West Fraser at their mill in Hinton, Alta. Integration of LignoForce into a mill involves re-balancing energy, water, steam, chemicals and Na/S ratio in the mill. Black liquor is sparged with oxygen then acidified with CO2, causing the lignin to come out of the solution in colloidal form. The coagulated lignin is dewatered in a filter press. The filter cake, in the sodium form, can be used as an ingredient in phenolic resins. Or lignin can be converted to the acid form, by washing with dilute sulphuric acid and water.

The LignoForce process has several advantages. Only one filtration stage is needed to produce high-quality lignin which reduces the capital cost. In addition, odorous total reduced sulphur (TRS) compounds are eliminated by converting them into more oxidized and non-volatile species such as thiosulphate, sulphate, methane sulphonic acid or dimethyl sulphone. This also reduces the need for CO2 to adjust pH in the lignin precipitation stage which significantly reduces the operating cost. Lignoforce produces high-quality lignin with low ash, carbohydrate and sulphur content and will work for black liquor from softwoods and hardwoods, including eucalyptus.

Lignin is being commercialized to partially replace fillers and phenol formaldehyde resin in plywood glue for board products, as well as in several other applications. The process allows for the production of TRS-free lignins in both basic and acid forms – each having unique applications. The basic lignin, which has high residual sodium content, is especially suited as a partial substitute for resins and fillers used in the manufacture of plywood. The acid form, with low residual sodium content, can be used for other applications such as partial replacement of isocyanate resins in the manufacture of fibreboard or phenol in the manufacture of phenolic resins.

TMP-Bio

In May 2019, FPInnovations and Resolute Forest Products announced the commissioning of a new thermomechanical pulp biorefinery, TMP-Bio, in Thunder Bay, Ontario, Canada. The plant, which has the capacity to treat 100 tonnes of biomass annually uses refining to open the fibres making them more accessible to enzymatic hydrolysis.

Whereas in chemical pulping, lignin and hemicelluloses are dissolved leaving cellulose fibres intact, TMP-Bio does the opposite, converting cellulose into sugars to preserve the lignin. The resulting lignin is less condensed than that from the kraft process and more closely resembles the original lignin in the tree. The sugars are then separated from the lignin, providing two streams of bio-sourced chemicals. Possible applications include adhesives; composites; animal feed; chemicals (e.g., monomeric and oligomeric phenol derivatives) from the near-native lignin; and chemicals (e.g., lactic acid, n-butanol) and bio-plastics for the C5 and C6 sugars.

FPInnovations tested the TMP-Bio process in a small-scale pilot plant in their facilities, using separate units to test different phases of the process. They used the results of these tests to design a larger-scale plant as the process needs to be tested on an industrial scale and a continuous basis. In an interview with Canadian Biomass (a sister publication of Pulp & Paper Canada) last year, Jean Hammel, vice-president of industry at FPInnovations, shared that the organization was able to identify 15 potential applications of this process. FPInnovations then decided to focus on testing four or five of those applications.

In 2020, Resolute was recognized with a silver Edison Award for this innovative plant.

In summary, research and development are enabling higher value products from lignin. The future looks promising with Canada playing a leading role.

Interested in learning more? FPInnovations’ Thunder Bay demonstration plant is sized to produce up to 50 ODkg/day of kraft lignin and has the capacity to treat 100 metric tons of biomass annually, to produce sugars and near-native lignin from the TMP-Bio process. Both operate on a semi-continuous basis. The kraft lignin pilot plant offers the flexibility to test black liquors from external mills to produce kraft lignin in the base form as well as lignin in the acid form. Through extensive knowledge in lignin-based product development, FPInnovations can help companies develop greener solutions by incorporating lignin into their products.

For business development information on lignin, please contact Natacha.Mongeau@fpinnovations.ca.

Print this page