Products

Maintenance & Reliability

Digital pneumatics introduced at Tissue World Miami

May 10, 2018 By P&PC staff

May 10, 2018 – A cyber-physical, pneumatic-motion control system was introduced to the paper converting industry by Festo at the recent Tissue World Miami 2018 conference.

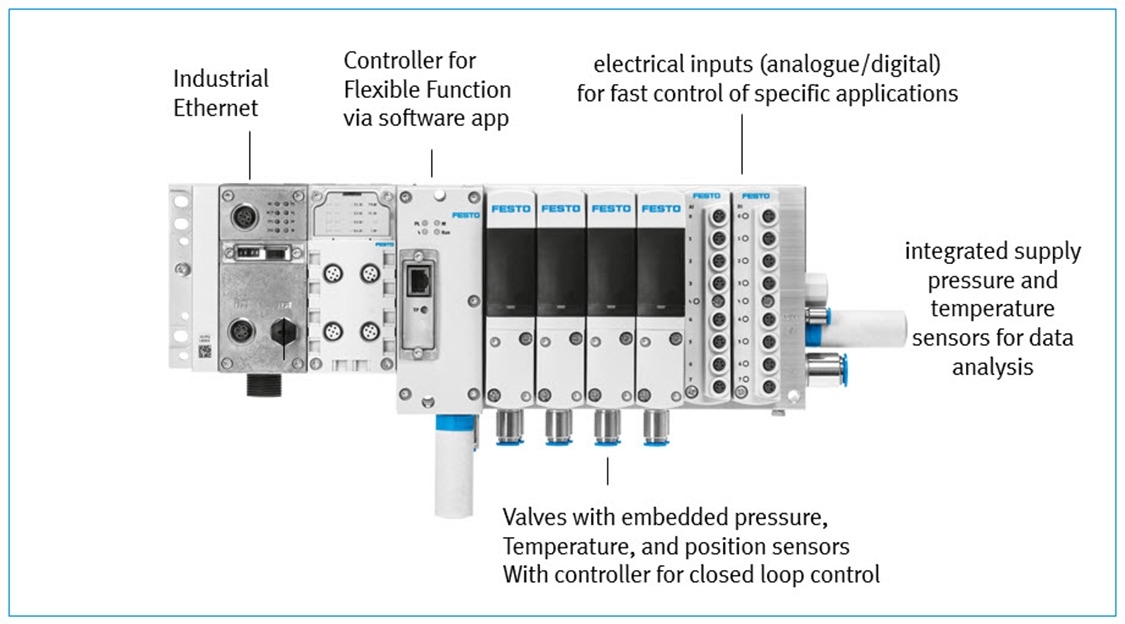

The VTEM Motion Terminal and several other new products were introduced at the event. The VTEM’s first-of-its-kind intelligent valves change functionality based on various combinations of downloadable motion applications. A single intelligent valve can replace 50 different components. The VTEM platform is modular and reconfigurable – thereby meeting two important criteria for systems based on Industry 4.0 and the Industrial Internet of Things (IIoT).

The capabilities of the VTEM Motion Terminal enable:

• Faster time to market for machine builders

• Fewer components to be sourced and maintained

• Faster installation and setup

• Greater machine flexibility

• Better energy efficiency

• Higher machine utilization

• Reuse and reconfiguration as conditions evolve

Motion apps seamlessly integrate computational algorithms with intelligent valves

Thanks to downloadable motion apps, one intelligent valve within the VTEM valve terminal can replicate traditional valve functions, including 2/2, 3/2, 4/2 or 4/3 way as well as proportional technology and servo-pneumatic functions. Flexible intelligent valves can also implement preset travel time, reduce costs by operating actuators with minimum pressure, and detect leaks for faster fault detection and less downtime.

Since changing parameters in this cyber-physical system doesn’t require a change in hardware, adaptation costs are kept within tight margins, even when changes are made after installation. The VTEM is offered in either four-valve or eight-valve platforms.

Ten motion apps are in the initial release with an additional 40 planned. Each app makes parameterization of a function faster and easier than current setup times. The apps in the first release provide the following functionalities:

• Directional control simulating the functions of the most utilized valves

• Proportional directional control valve

• Soft stop

• Proportional pressure regulation

• Model-based proportional pressure regulation

• Eco drive

• Selectable pressure level

• Leakage diagnostics

• Supply and exhaust air flow control

• Presetting travel time

“The VTEM is more than a one-to-one substitution of physical for cyber-based control,” Mark Schuster, Festo industry segment manager, printing, paper, and converting, said. “The VTEM Motion Terminal’s capabilities cost effectively move pneumatics in the paper converting industry into areas such as servo pneumatics and servo electrics as well as Industry 4.0 and IIoT.” The VTEM is a Rockwell Automation Encompass referenced product.

Additional Festo 2018 Tissue World introductions

Festo presented to the paper converting industry the EMCA, a compact, affordable integrated positioning drive optimized for automated format setting on paper converting machines and conveyor systems. These positioning drives operate within most communication architectures, including EtherNet IP. The EMCA is available for fast shipping, lowering inventory requirements, and features quick and easy commissioning as well as world class Festo quality construction and global support.

The CTEU-EP universal interface module from Festo makes EtherNet/IP and Profinet connectivity low cost and plug and play for IO-Link devices and Festo valve terminals. For maximum flexibility, OEMs can cost effectively integrate IO-Link devices such as pressure and flow sensors, RFID readers, light stacks, and valve terminals. With a splitter, two-valve terminals can be served. The CTEU-EP is Open Device Vendors Association (ODVA) conformant and is a Rockwell Automation Encompass referenced product.

Festo showcased at Tissue World its comprehensive air preparation systems for lower energy usage and fewer operational issues over the life of the system. Additionally, booth personnel detailed for show attendees the operating advantages of the new MSE6-E2M intelligent service unit that automatically detects leaks and also shuts off the air supply to a machine when in standby mode, both of which contribute to lower energy consumption.

Festo featured its expanded line of intelligent process automation valve terminals and the company’s Stars of Automation program that guarantees 24-hour shipment of core products. Guaranteed fast shipment across the globe from regionally based distribution centres lowers overhead as fewer replacement components must be carried in inventory. This program also simplifies and speeds up ordering and rationalizes components, reducing time to market for OEMs.

Print this page