Features

Workforce

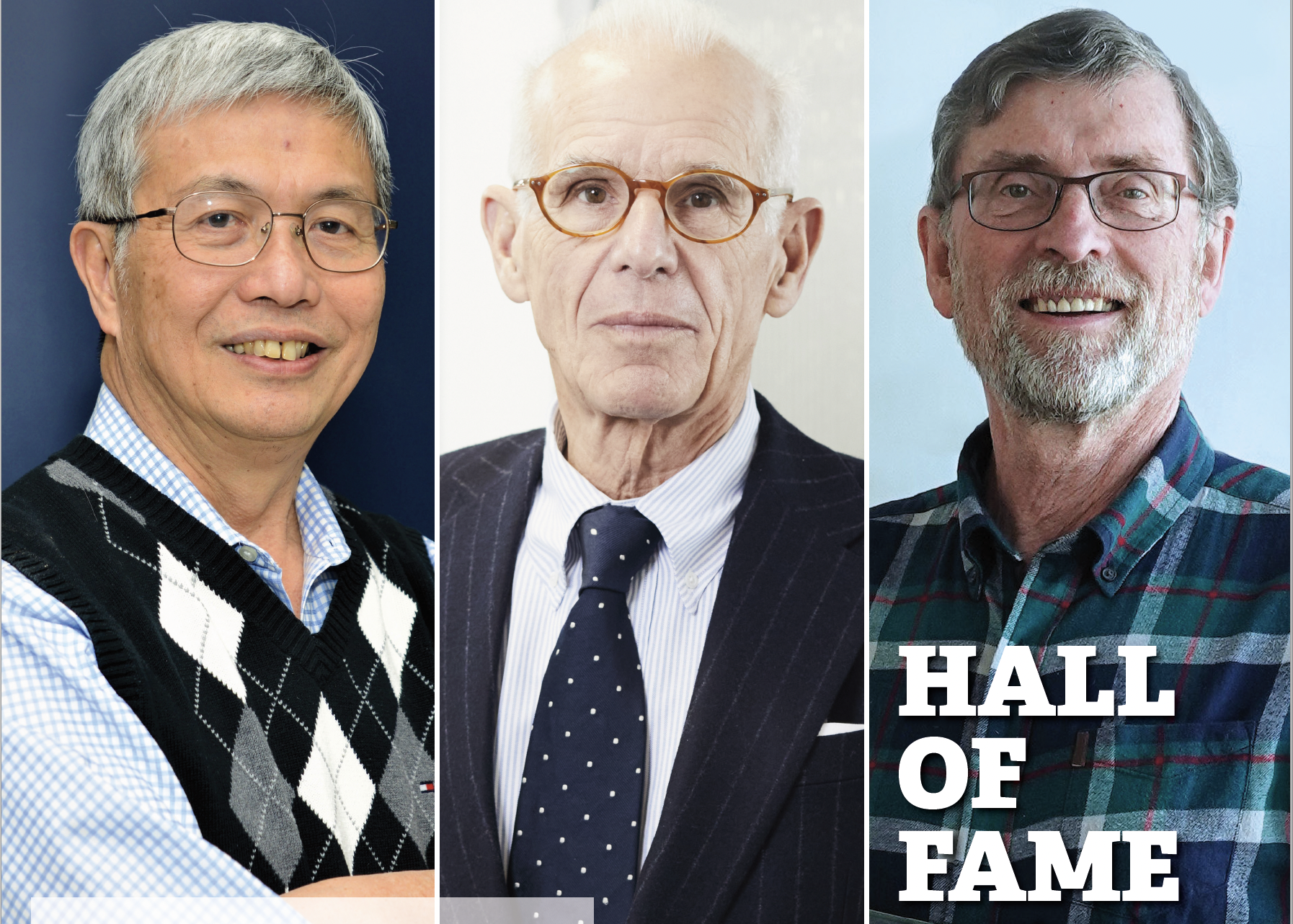

Hall of Fame 2022: Honouring the legends of the pulp and paper industry

Meet the winners of Pulp & Paper Canada’s inaugural Hall of Fame contest.

April 20, 2022 By Sukanya Ray Ghosh

The Canadian pulp and paper industry is standing strong and thriving because of the immense efforts of the incredible workforce. Over the years, several industry leaders and innovators have revolutionized the industry, taken it forward and have been the pillars on which the sector has built its success. The inaugural Hall of Fame contest celebrates and honours three such legends who have spent several decades contributing to its growth and inspiring generations of people after them.

These legends are so passionate about being a part of the pulp and paper industry that they continue to contribute with equal zeal even today. Read about their amazing journey and how they changed the industry.

LARRY WASIK

President, Aurel Systems Inc.

Larry Wasik’s 49-year-journey in the pulp and paper industry started with his interest in computers. After graduating from the University of British Columbia as a chemical engineer, Wasik’s friend told him about a position at Canfor’s Port Mellon Pulp Mill that required a person knowledgeable in computers to do process control.

Larry Wasik, president of Aurel Systems Inc.

Photo: Larry Wasik

Wasik joined the computer control team and later became the assistant technical superintendent, overseeing the mill’s environmental programs and computerized process control developments. In 1972, he created his first process simulator to be used in process control at the mill.

In 1980, Wasik joined a consulting group, H.A. Simons, as a consulting engineer. It was here that he started his other career – creating tools that people could use to improve the processes in pulp and paper. In the 15 years he spent in the company, Wasik went on to become a plant-wide process manager, spearheading the plant-wide process design of five successful green field mills and numerous re-builds and culminating in the $1.3 billion expansion at Howe Sound Pulp and Paper.

Wasik has played a lead role in on-site process optimization studies in North American mills as well as in Brazil, Australia, New Zealand and Siberia. In parallel, he led Simons’ computer process simulation department using CADSIM, a graphical interface program he developed in 1986, combined with MASSBAL steady-state simulator. He specialized in developing first principles balances for all aspects of pulp and paper mills.

Wasik’s overall material balances; water and energy balances; sodium, sulphur, potassium, chloride and metal ion balances; and pulping and bleaching balances became standards that are still used in the industry today. By 1996, he had developed a stand-alone dynamic process simulator, CADSIM Plus that has become a leading technology for pulp and paper simulations.

Wasik has provided process simulation services to engineering consultants and operators in various capacities working as an employee, consulting engineer and principle of his own research company, Aurel Systems Inc. He has developed a steam and power dynamic simulation for the reduction of steam demand swings at Kapuskasing. He developed online dynamic data reconciliation for the plant-wide energy system at Crofton and for batch digesters at Temiscaming. Moreover, he has trained and assisted numerous operating and consulting companies in the use of process simulation. Wasik has also donated countless copies of CADSIM Plus to universities and technical institutions around the world through Aurel’s Academic Software Program.

“An interesting fact that stands out to me is that Larry has had an indirect impact on shutting down four fossil-fired power boilers in British Columbia. This is a testament to the energy savings and reduced environmental impacts attained through optimization that are still to this day made possible using the CADSIM Plus dynamic process simulator,” adds Daenzer.

As a member of organizations such as TAPPI, PAPTAC and PACWEST, Wasik continues to be involved through conferences and trade shows, always seeking new opportunities to connect with members and foster partnerships.

Wasik, still very passionate about innovating, considers the process simulator his most significant contribution to the pulp and paper industry.

“Coming from a time when calculations were done on a spreadsheet or a calculator or by hand, and putting graphics in front of that and making the graphics interpreted was certainly both challenging and interesting to me,” says Wasik.

Despite the process simulator being highly successful, Wasik has not stopped innovating further. Currently, he is leading his team at Aurel Systems Inc. to research the ability to track a process live. His team has developed the ability to track the process and do real-time optimization with it.

“We’re now positioning it as a process control tool that could work right alongside the process and make sense out of the data. That’s a huge effort that we’ve put about nine man-years of research into,” he shares.

Wasik also enjoys mentoring young talent coming into the industry. He recalls mentoring a bright young person at Port Mellon. He hired him, shared his experience and now takes pride in the fact that his mentee did very well at the mill. At H.A. Simons, when he was working on his software, he had nine young engineers working there who he was able to motivate and inspire. At Aurel Systems Inc., Wasik takes in summer students on a regular basis and enjoys seeing them grow.

When asked about what’s next for him, Wasik says that at some point he has to retire. “I’m still working on developing some bits of the tool, pushing its limits, making it faster, so it can track the processes, and do real-time optimization. And my focus is on getting the younger people that are in our company to do all the things that I do and launch increasingly better tool sets.”

HONGHI TRAN

Professor emeritus and director of the pulp and paper centre, University of Toronto

A renowned researcher, Dr. Hongi Tran’s contribution to the Canadian pulp and paper industry has been immense throughout his career. Tran’s entry into the industry is quite an interesting story. Originally from Japan, Tran received his Master’s Degree from Shizuoka University in Japan and went on to work in the glass industry.

Honghi Tran, professor emeritus and director, Pulp & Paper Centre at University of Toronto

Photo: Honghi Tran

When he arrived in Canada in 1978, he was initially unable to find a job in his field. Tran decided to go back to university and study further to build a proper career. He joined the University of Toronto, where a professor who specialized in ceramic engineering was highly impressed with his work in Japan and the thesis he had written there. He offered Tran a position on a project. The project was to take a look at how a superheated tube got corroded in the recovery boiler in a pulp and paper mill in Thunder Bay.

With no knowledge of pulp and paper mills, he turned to his experience in the glass industry and was able to figure out what went wrong. Three years later, Tran presented at an international chemical recovery conference in Vancouver and instantly became famous. He graduated with a Ph.D. in Chemical Engineering from the University of Toronto and was hired by Douglas Reeve & Associates, a Toronto consulting company. His work took him to kraft pulp mills in Canada, the U.S. and even Brazil.

Tran’s research focus is on energy and chemical recovery in kraft pulp mills. By applying fundamental knowledge obtained from university research to industrial settings, he has helped solve numerous operating issues in the chemical recovery process.

Tran’s research group was responsible for the development of high-intensity sootblowing nozzles which greatly enhanced the cleaning ability in recovery boilers, as well as the low pressure sootblowing technology and partial borate autocausticizing technology.

“His theory and practical knowledge in kiln and recausticizing operations have led to key operational parameters to improve white liquor production while minimizing scaling and plugging, ring formation in kiln and dusting in kilns,” says Thanh Trung, University of Toronto Research Consortium member and collaborator.

Over a career spanning more than four decades, Tran successfully established and directed eleven consecutive research consortia at the University of Toronto and obtained support from over 50 companies from eight countries. His research was supported by various government agencies, including the Natural Sciences and Engineering Research Council of Canada (NSERC), Industry Canada the American Forest and Paper Association and the Department of Energy.

Through his leadership, Tran has supervised/co-supervised over 130 graduate students, post-doctoral fellows and research staff and 100 undergraduate students. He has authored/co-authored over 310 refereed papers and a textbook and has eight patents.

In addition to his academic duties, Tran has served on and chaired numerous committees, international meetings and conferences, including as program chair of the 1995 International Chemical Recovery Conference (ICRC), and as conference chair of the 2008 ICRC. He has been an instructor of the annual Kraft Recovery Course held by the Technical Association of the Pulp and Paper Industry (TAPPI) since its establishment in 1987 and has chaired the course since 2006. He was the first chair of the council of directors for the Canadian Pulp and Paper Network for Innovation in Education and Research (PAPIER), an alliance of eight major pulp and paper centres in Canada. He also served as the inaugural editor-in-chief of the Journal of Science and Technology for Forest Products and Processes (J-FOR) published by PAPTAC (Pulp and Paper Technical Association of Canada) from 2011 to 2014.

Tran and his research consortium have led the way with innovative solutions for the pulp and paper industry, particularly in the area of chemical and energy, for many years. Through the consortium, the group is able to bring in real industrial problems and address the core issues by breaking down the problem to fundamental issues to device solvable and, more importantly, implementable solutions for the industry. His latest research is moving the focus of the research consortium to innovative bio-energy and bio-fuel.

Tran has won numerous prestigious awards for his contribution to the pulp and paper industry. These include the 2013 John S. Bates Gold Medal from PAPTAC, the 2017 Gunnar Nicholson Gold Medal from TAPPI, the 2014 ICRC “Lifetime Achievements and Contributions” Award, and the 2020 American Forest & Paper Association (AF&PA) Leadership Award for “Advancing the understanding of kraft recovery boiler technology, operation and safety”.

He was named a TAPPI Fellow in 2000, one of the first PAPTAC fellows in 2015, and a Canadian Academy of Engineering Fellow in 2016. He was inducted to the Paper Industry International Hall of Fame in 2017 and the Engineering Alumni Network (EAN) Hall of Distinction, the University of Toronto in 2021. He was recently named to the 2021 Paper 360o Top 50 Power List.

To the young generation looking to join the industry, he says, “I believe that if I can do it, anybody can do it. The industry has many challenges. So, it is very exciting to work here if you want to help the industry or society. Any type of engineer would be able to find a good fit in the pulp and paper industry.”

JOSEPH KRUGER II

Chairman of the board and CEO, Kruger Inc.

Joseph Kruger II was born into the pulp and paper industry and has been a recognized leader for several decades now. His grandfather Joseph Kruger, a paper merchant, founded the company in 1904. His father, Gene H. Kruger took over the company in the late 1920s and took it forward.

“I often joke that I spent the first 20 years of my career carrying my father’s briefcase. He was my mentor and I learned everything by his side. My father, Gene H. Kruger, truly was a visionary and a builder. He had such courage and determination to succeed,” says Joseph.

Joseph Kruger II, chairman of the board and CEO of Kruger Inc.

Photo: Kruger Inc.

For several decades, Joseph Kruger II has been a leader whose vision, business acumen and entrepreneurial courage were the driving forces behind Kruger Inc.’s transformation into one the most innovative and sustainable paper companies in Canada.

Early on, Joseph had the foresight to recognize how the rise of information technology would affect Kruger Inc.’s legacy business sectors. He led the company on a successful journey of diversification that began with a bold decision: the acquisition of Scott Paper’s Canadian assets, in 1997. These would later come to be known as Kruger Products.

In the following years, he led the company through a succession of acquisitions and major capital projects that not only strengthened its foundation but enabled it to keep all of its paper plants in operation through the Great Recession, and then to embark on a period of unprecedented transformation.

Today, Kruger Inc. is a leading supplier of newsprint, coated paper, containerboard and corrugated packaging, in addition to being at the forefront of the circular economy as one of Canada’s largest paper recyclers. It is also a pioneer in the manufacture of cellulose filaments and the development of new eco-friendly specialty papers.

Over the years, Joseph Kruger II earned the admiration of colleagues and peers as one of the most innovative and progressive entrepreneurs in Canada. He is seen as a caring leader concerned with protecting the environment and resources, and with securing the future of the company for the benefit of future generations.

“Joseph Kruger II is truly a Canadian icon and a pillar of the Quebec community, employing multigenerational families and committed to supporting the livelihood of many people. Although very private, he has been recognized as a brilliant business entrepreneur who has expanded the company beyond its pulp and paper origins. Truly one of a kind, he is a visionary with a pragmatic perspective, indelible memory and creative flair,” says Nancy Marcus, Kruger Product’s former chief marketing officer.

Joseph led the company as a fearless business leader whose determination to sustain all of Kruger Inc.’s paper mills during the 2008 global financial crisis led to the preservation of strategic manufacturing assets, including the Trois-Rivieres, Wayagamack and Corner Brook plants.

Today, these facilities are still in operation, providing quality jobs and contributing to the economy of the communities they call home. They have also been key components in the company’s strategy for future growth and expansion, with such milestones as the 2017 rebuild of Kruger’s largest newsprint machine, PM10, into a high-performance linerboard machine, and the recent creation of a new specialty papers division.

Under Joseph’s leadership, Kruger Inc. has become increasingly focused on sustainable practices, technological upgrades, product development and, more recently, the integration of artificial intelligence capabilities, making it a key player in the modernization of the Canadian pulp and paper industry.

Joseph also prioritizes knowledge transfer and education through various scholarships, internship programs and research funding. The company also works in partnership with industry associations, research chairs and business startups to conduct R&D.

About his entrepreneurial courage, Francois D’Amours, Kruger Inc.’s executive vice-president and chief operating officer, says, “I have a lot of admiration for our leader who had the courage to maintain all of our paper mills through the worst crisis in our industry, as well as the vision and audacity to diversify the business. Very few leaders could say that they re-shaped their company the way Mr. Kruger did, like a true builder with remarkable business intelligence. He has definitely given Kruger a solid foundation for another 100 years of success.”

Known for having an insatiable thirst for new ideas, Joseph Kruger II has always fostered a culture of innovation at Kruger Inc. As a result, the company has invested in and built some of the most innovative pulp and paper manufacturing technology in the past three decades.

Prominent examples include Wayagamack’s PM4, which remains one of the best paper machines in the world nearly 18 years after its commissioning; Trois-Riviere’s PM10, which was entirely rebuilt in 2017 to manufacture Kruger’s exclusive XTR linerboard; and, most recently, Kruger Products’ new state-of-the-art Sherbrooke Tissue Plant featuring a highly advanced TAD tissue machine.

When asked what message he has for the pulp and paper industry, Joseph says, “Respect your employees and care for them; never neglect your customers; invest in new technology; focus on climate change; and let’s be proud of who we are – we make essential products.”

Print this page