Features

Paper

Pulp

Research & Innovation

Tissue

Workforce

Hall of Fame 2023: The inspiring winners and legends of the industry

April 24, 2023 By Sukanya Ray Ghosh

The inspiring leaders at the helm of the Canadian pulp and paper industry have set impressive benchmarks for success for the newer generation of the workforce. They have contributed to ground-breaking innovations through their deep commitment to and passion for growing the sector.

Pulp & Paper Canada’s Hall of Fame contest celebrates and honours three such legends annually. Read how these changemakers have helped the industry evolve positively through their hard work and zeal.

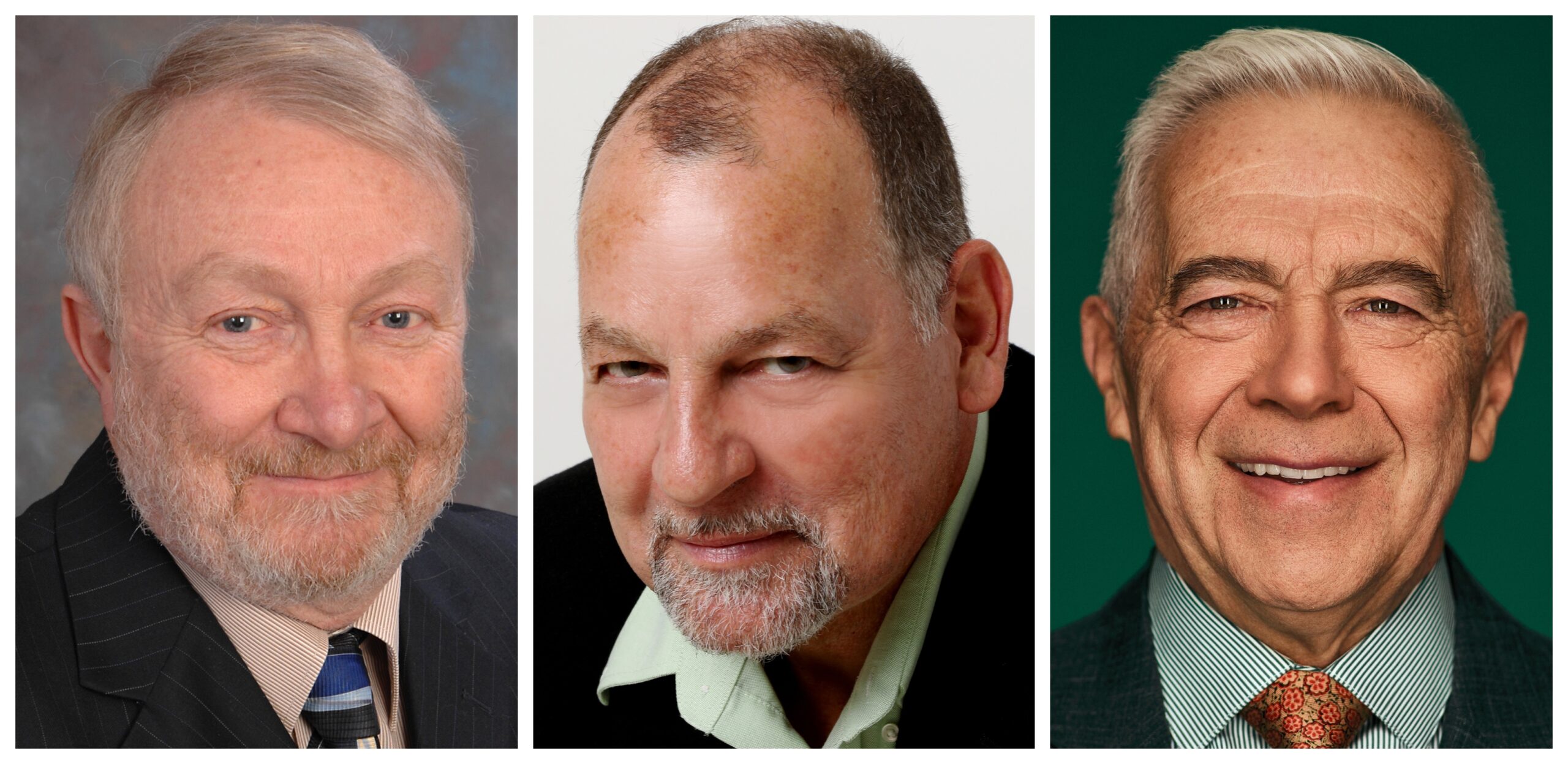

J. DAVID MCDONALD

Consultant and adjunct professor, Chemical Engineering department at McMaster University

J. David McDonald

J. David McDonald has spent 45 years in the pulp and paper industry with Abitibi-Price, Paprican and FPInnovations as a scientist, manager and executive. He is currently a consultant and an adjunct professor in the Chemical Engineering department at McMaster University.

McDonald’s application for a job opening as a Mathematician with the Abitibi Paper Company at their research centre in Sheridan Park west of Toronto marked his entry into this industry.

While at Abitibi, currently a part of Resolute, he developed an on-line computer system for measuring the quality of paper rolls on the winder, a mathematical model to significantly reduce calender barring and pressing and drying strategies to reduce linting, all of which were applied company-wide.

McDonald later joined Paprican as a scientist working on paper machine pressing. Working with Ivan Pikulik, he helped identify the press section factors that affect paper quality. In addition, by means of unique pilot paper machine experiments, they identified the mechanism of paper adhesion to press roll materials which supported the transition from granite to ceramic and metal rolls. With Dick Kerekes, he challenged the conventional picture of press dewatering which led to a practical model currently used by machine builders, consultants and papermakers, worldwide.

McDonald gained experience in management, first leading a small group in calendering and winding which did seminal research in minimizing paper defects and web and roll handing. Later, as the program manager of Paprican’s Mechanical Pulping Program, he managed 25 people and transformed the group from one that produced good science to one that applied their discoveries in commercial applications.

McDonald was selected for executive positions at Paprican and later, FPInnovations. As vice-president of research and education of Paprican, he directed Paprican’s research program with line responsibility for 310 research staff. As vice-president of university programs and strategic partnerships of FPInnovations, he formulated the vision for the Transformative Technologies Initiative.

McDonald has written 87 peer-reviewed publications of which 28 were published in Pulp & Paper Canada. Of those published in PPC, two have received the I.H. Weldon gold medal for best overall paper, the Jasper Mardon award for the best papermaking paper and John Bates award for the best paper presented at a branch meeting.

He received the highest technical awards, the John Bates Gold Medal from PAPTAC and, the Gunnar Nicholson Gold Medal from TAPPI, for his major contributions in research and leadership. In addition to being a fellow and life member of both organizations, TAPPI recognized him with the Aiken Prize for outstanding contributions to research and development as well as the Engineering Division Award and Beloit Prize.

JOHN MULLINDER

Former executive director, Paper and Paperboard Packaging Environmental Council (currently retired)

John Mullinder

John Mullinder led Canada’s national environmental council for the paper packaging industry (PPEC) for 30 years, from 1990 to 2020. He worked closely with the country’s packaging mills and converters, identifying their environmental requirements and providing them with timely information and intelligence. He has been prolific in educating the industry, its customers, governments and the general public on paper’s sustainability story through online blogs, letters to the editor, and on the PPEC (and more recently his own website: johnmullinder.ca).

He has also published two books on industry issues, educating readers on the facts of deforestation, and evaluating current environmental buzzwords and exposing greenwashing where it occurs: Deforestation in Canada and Other Fake News (2018) and Little Green Lies: From “Ancient” Forests to “Zero” Waste (2021).

Mullinder represented the industry on Canada’s National Task Force on Packaging between 1991 and 2000; participated in various Canadian Council of Ministers of the Environment (CCME) committees and stakeholder groups; chaired the innovative Boxboard Task Group; and was a director on the boards of both the Recycling Council of Ontario and Waste Diversion Ontario for several years.

In the early 1990s, most of old boxboard ended up in landfills. Mullinder chaired and steered the efforts of the innovative Boxboard Task Group committee of packaging mills and their brand owner customers that led the world in further recycling old boxboard. Working with brand owners, PPEC undertook pilot trials at Strathcona Paper and Paperboard Industries. It developed a Food Packaging Protocol to give the brand owners confidence that re-using residential boxboard in new food packaging would not be a health concern. Mullinder then worked to persuade other mills such as Atlantic Packaging to use old boxboard as filler material in their manufacture of corrugated board.

While at PPEC, Mullinder initiated several North American or world “firsts.” PPEC was successful in promoting the introduction of activity-based costing to industry-funded Blue Box programs across the country. PPEC was the first paper packaging association in the world whose entire mill membership was independently third-party certified to internationally recognized “chain-of-custody” standards. PPEC was also the first packaging association in Canada to publicly call for landfill bans on the type of packaging material its own members produced.

“I like to dig for the facts, to understand the situation as best I can, and often there are several sides to a story. The industry has a major education job ahead of it. I mean, one environmental group is telling people today that paper packaging is mostly made from market pulp taken from 1,000-year-old trees. For a start, most trees in Canada are under 100 years old. And secondly, most paper packaging in Canada is already 100 percent recycled content,” says Mullinder.

ALAIN LEMAIRE

Cofounder and executive chairman of the board of directors, Cascades

Alain Lemaire

Alain Lemaire learned the importance of material recycling and recovery from a young age through his involvement in his family’s household waste recovery business. He developed the profoundly human values that underpin Cascades’ international growth today. Lemaire’s actions, and those of the company he co-founded with his brothers Bernard and Laurent in 1964, are guided by the values of respect, teamwork, fierce determination and communication combined with a deep-seated belief in sustainable development.

Lemaire studied at the Institut des pâtes et papiers (pulp and paper institute) in Trois-Rivières. By keeping close to operations and focusing his actions on efficiency, he expanded his expertise in business development and recovery. In 2003, he was the third and last Lemaire brother to take the helm at Cascades.

An experienced leader and extremely logical thinker, Lemaire orchestrated the development of the Fine Papers Group and the continued growth of Norampac, which is now known as Cascades Containerboard Packaging. In 2006, under his leadership, Cascades proceeded to buy back Domtar’s stake in Norampac (Cascades Containerboard Packaging).

“My brothers entrusted me with the task of consolidating two cultures and achieving the expected synergies. By selecting the best elements, we were able to build a winning team. It was an exciting success! This entity later became a full-fledged Cascades property,” shares Lemaire.

He also participated in the development of Cascades’ most important investment to date: the Greenpac mill, a modern mill featuring the latest technologies in paper manufacturing.

Lemaire, along with his brothers, is a North American pioneer in recovery and recycling. Thanks to their vision, in the 1960s, Cascades began manufacturing paper from recycled fibres. They made their business model a system they called “the closed loop” which consists of recovering old paper and giving it a second life by making new recyclable paper. They were practicing circular economy decades before the concept was born and popularized.

Throughout his career, Lemaire has spent a lot of time on the plant floor. He knows the equipment, the work methods and the names of many employees and their families. His operating skills have served him well in plant acquisitions. He has repeatedly demonstrated his ability to acquire and make assets profitable. He was able to breathe new life and innovation into Cascades’ processes and, more globally, into the entire pulp and paper industry.

“What still motivates me are the people around us who, through their involvement, encourage us to do more and do better. These employees dedicated on all levels have at heart customer satisfaction, especially in terms of service quality. These are the same people who, through their skills, leadership, empathy and communication skills, will make a difference and will define the industry’s success,” says Lemaire.

Print this page