News

How to lower operating costs in drying and blow-off operations

September 1, 2009 By Pulp & Paper Canada

A new white paper published by Spraying Systems Co. takes an in-depth look at how to reduce or eliminate compressed air use in drying and blow-off applications and achieve dramatic savings. Replacing …

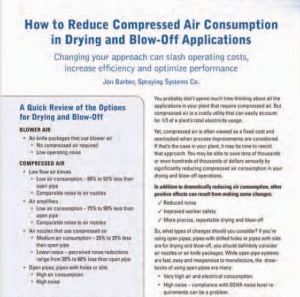

A new white paper published by Spraying Systems Co. takes an in-depth look at how to reduce or eliminate compressed air use in drying and blow-off applications and achieve dramatic savings. Replacing open pipe with manifolds equipped with air nozzles or air knife packages powered by blower air often results in savings of tens of thousands of dollars per year.

The paper reviews various air nozzle options that use compressed air, provides application guidelines and estimates the savings each option offers over open pipe. Products discussed include air nozzles that produce a high-impact air stream and are ideal for moving materials and cleaning, drying and cooling parts; variable air amplifiers that produce a constant, high-velocity air stream for very targeted drying and blow-off; and low-flow air knives that produce a uniform, high-velocity air flow across the entire length of the knife.

Spraying Systems Co. 630-665-5000, www.spray.com/savewaterandair

Print this page