Features

Research & Innovation

Built-in flexibility helps

When the mill was rebuilt in 1983, it was designed to be flexible. This certainly helped make the switch to dissolving pulp easier. Also, although it has been more than 15 years since the mill was reb...

April 1, 1999 By Pulp & Paper Canada

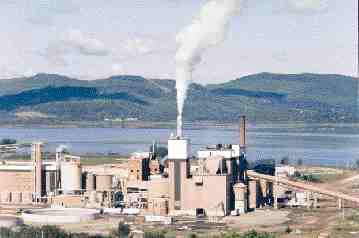

When the mill was rebuilt in 1983, it was designed to be flexible. This certainly helped make the switch to dissolving pulp easier. Also, although it has been more than 15 years since the mill was rebuilt, the equipment has a lot fewer years of operation as the mill was idled for at least seven years.

As part of the modernization, new chip handling facilities were added. Other changes included: the addition of steam packers to each of the five digesters; new brownstock washing/screening equipment; new four-stage bleachery; a new three-stage screening and four-stage centrifugal cleaning system; new chlorine dioxide plant and sodium hypochlorite makedown system; upgrades to both both pulp machines and a new Flakt dryer at the end of No. 2; a new recovery island – evaporators, liquor recovery, recovery boiler, acid plant; new power boiler.P&PC

The mill went through an extensive modernization in the early 1980s.

Print this page