Products

Test & Measurement

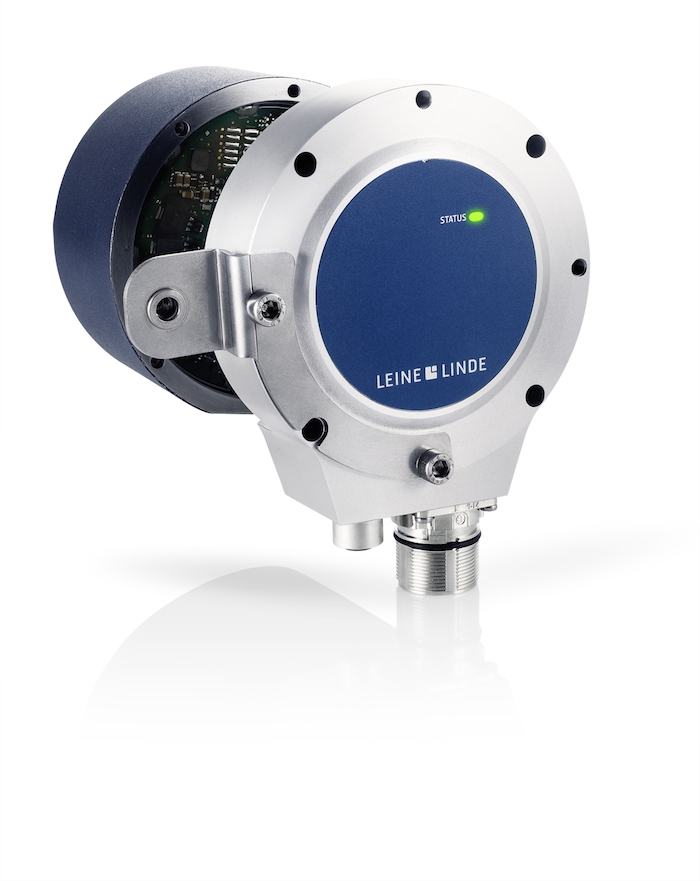

Leine & Linde Advanced Diagnostic System for paper mill production

May 5, 2017 By P&PC Staff

May 5, 2017 – In an effort to help paper mills increase their condition monitoring capability, Leine & Linde has announced an integrated Advanced Diagnostic System (ADS Online), which monitors various environmental and operational parameters of the encoder and reports this information to the system operator.

The result of this system is more efficient production, says Leine & Linde, as maintenance and operational personnel will be able to plan preventative maintenance during scheduled maintenance cycles to further evaluate and replace encoders. Utilizing the new ADS Online, Leine & Linde 800 rotary encoder series promises to provide additional problem-solving information. Until now, Leine & Linde’s ADS Online capabilities have only been offered as an optional module for existing encoders. The newest 850 shaft encoder and the 861/862 hollow-shaft encoder versions now have this functionality as a standard.

The addition of online access to the current capabilities of Advanced Diagnostic System (ADS) also boasts enhanced functionality with vibration and temperature monitoring. ADS Online monitors various parameters of encoder function such as: output voltage level is correct, output states change correctly, the correct number of pulses are present each revolution, and that the optics performs within defined levels for supply current and brightness. In addition, vibration levels, hours of operation and internal temperature are also measured and logged. The operator can set alarm levels on any of these parameters, as well as set logging intervals for trend evaluation.

Print this page