Products

Equipment & Systems

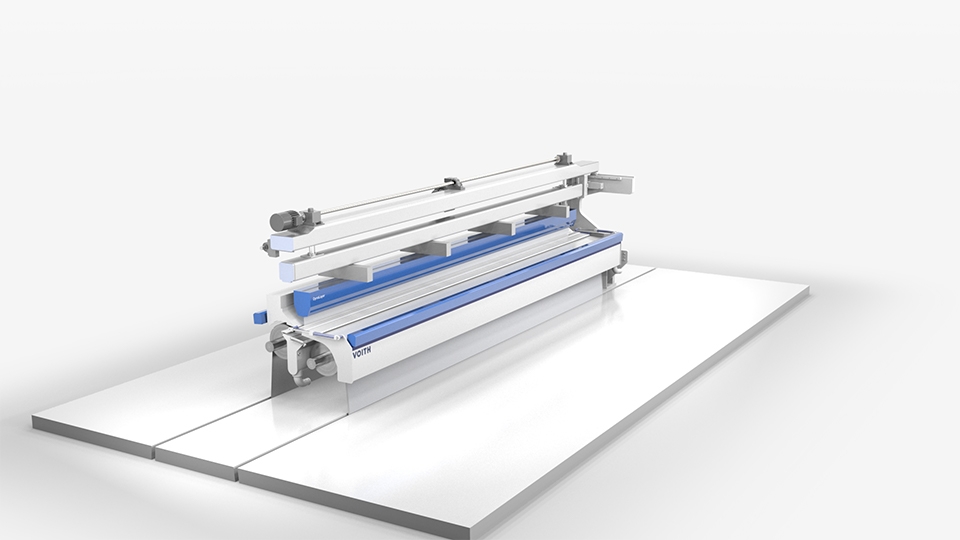

Curtain coater works without additional enclosure

June 29, 2018 By P&PC staff

June 29, 2018 – Voith’s new DynaLayer is an easy-to-use coater that achieves ideal colour application without an additional enclosure, resulting in improved cost efficiency of paper production and an efficient alternative to conventional coaters.

The product achieves a particularly uniform coverage of the web with just one layer. In addition, unlike previous curtain coaters, DynaLayer can be operated without an enclosure, which not only improves access for the operator but also results in much lower operational and maintenance costs.

A nozzle insulation cover specially developed by Voith and featuring air purging on both sides prevents condensation on the nozzle lips which could impair the quality of the coating application. In addition, Voith has introduced the concept of air shielding, where a transparent air barrier shields the sensitive curtain against disruptive outside influences and therefore makes an additional enclosure unnecessary. Moreover, the operator can reach through the air shield at any time without causing turbulence or impairing coating quality.

At the same time, the latest generation of curtain coaters allows even more uniform CD and MD profiles to be achieved. This has a positive effect on the printability of the paper and produces a more homogeneous printed image. The number of costly web breaks is also reduced when using DynaLayer thanks to the non-contacting application of the coating.

Cost savings at paper manufacturers

“Several manufacturers of specialty papers have already reported cost savings to us as a result of considerably reduced color consumption,” Christoph Henninger, product manager coater stations at Voith, said.

The uniform colour application by the new curtain coater is also useful when producing white board with a two-layer coating. To achieve a high surface opacity in these kinds of papers, most manufacturers currently use titanium dioxide. However, this is an expensive pigment, so any reduction improves the economic efficiency of the system. For example, a paper manufacturer that has been using the DynaLayer for some time now cut the costs for titanium dioxide by about half for the production of board with a white top layer by completely dispensing with the titanium dioxide in the bottom coating layer while ensuring the same quality of coverage. A similar effect was achieved by a manufacturer of specialty papers that is saving up to EUR 150,000 per year thanks to the uniform application of the coating of the expensive functional layers, because the total colour application could be reduced as a result of better CD profiles.

DynaLayer product family meets different customer requirements

According to the individual requirements and applications of paper producers, Voith offers the new curtain coater in various models. This means that DynaLayer can be supplied as the latest model without enclosure or in the previous variant with enclosure. The coating unit generally achieves a perfect application with just one layer. If required, for example in the case of two different coatings, DynaLayer is available as a two-layer concept that can also be easily retrofitted.

Voith Paper is a group division of Voith and a leading partner and pioneer in the paper industry.

Print this page