News

Packaging

ABB to deliver drive system for Kruger rebuild

April 12, 2016 By Cindy Macdonald

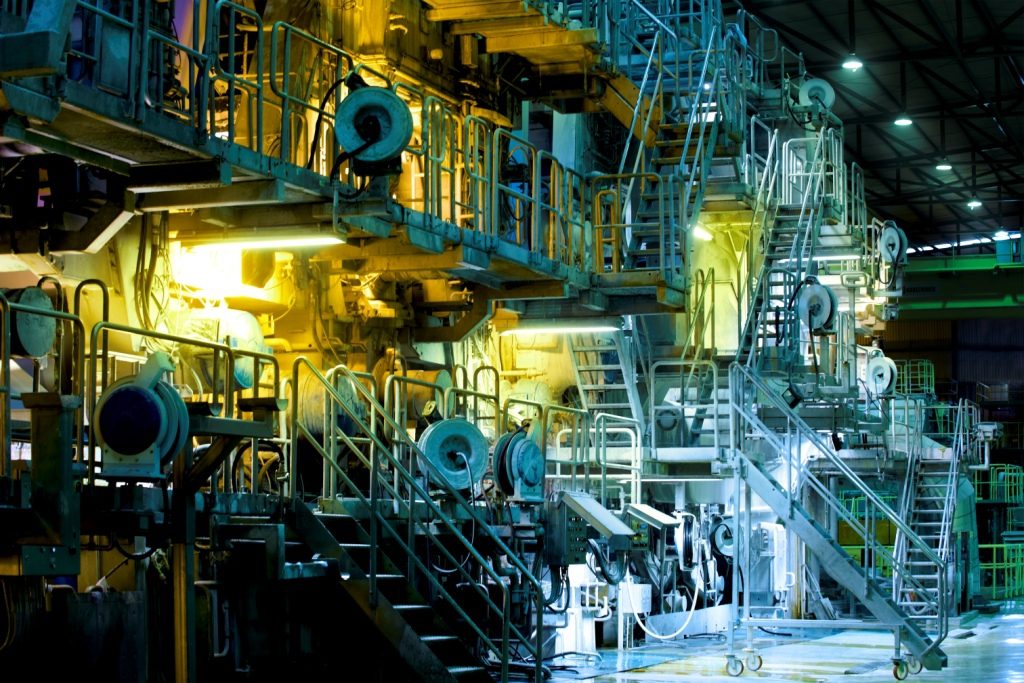

File photo courtesy of ABB.

File photo courtesy of ABB. ABB has been chosen as one of the suppliers for the paper machine rebuild project at Kruger’s Trois-Rivières Mill in Quebec. The project is part of Kruger’s $250-million investment to rebuild its No. 10 newsprint machine (PM10) to manufacture 100-per-cent-recycled, lightweight high-strength linerboard. Once the conversion is complete, PM 10 will produce 360,000 metric tonnes of linerboard annually for use in Kruger’s box plants and for the global packaging market.

ABB will deliver and install drive systems for PM 10 and its winder. The scope of supply for this rebuilding project includes ACS880 MultiDrive line-ups, AC motors, System 800xA control system, supervisory systems, remote diagnostic services, high-speed data logging system, spare parts and local engineering, commissioning, installation supervision and start-up service.

Kruger Packaging opted for a state-of-the-art AC drive system, which will replace the existing DC drive system currently on PM 10.

“We have chosen ABB for their excellent engineering and service team, as well as their extensive knowledge and experience in delivering proven technology for a number of our projects,” said Christian Lemay, Kruger project manager.

ABB says its ACS880 drive technology, coupled with its direct torque control (DTC) technology, provides unsurpassed motor control performance, supported with best in class uptimes. This contributes to energy efficient, highly reliable systems.

“The ABB project delivery and engineering team has a strong, trusted relationship and great working history with Kruger,” said Jim Fisher, head of ABB’s Pulp & Paper business. “We look forward to delivery of yet another successful project which will produce energy efficiencies and reduced maintenance costs for Kruger.”

Kruger Packaging L.P. is a Canadian manufacturer of containerboard and packaging products made from recycled fibers.

Print this page