Features

Bioeconomy

Opinion: Sustainable bioproducts in concrete

November 23, 2021 By FPInnovations

Cement paste prism for shrinkage measurement containing cellulose fibre.

Photo: FPInnovations

Cement paste prism for shrinkage measurement containing cellulose fibre.

Photo: FPInnovations

The role of sustainable bio-sourced materials in creating a circular bioeconomy is increasingly recognized globally. Integrating local bio-sourced products in concrete applications has specifically been a growing interest for the Canadian government and industry.

In its efforts to introduce forest-based biomaterials to new markets, FPInnovations developed expertise in concrete over the past few years and has been working with the pulp and paper and the concrete industries towards the use of innovative bioproducts in concrete applications.

Global market trend

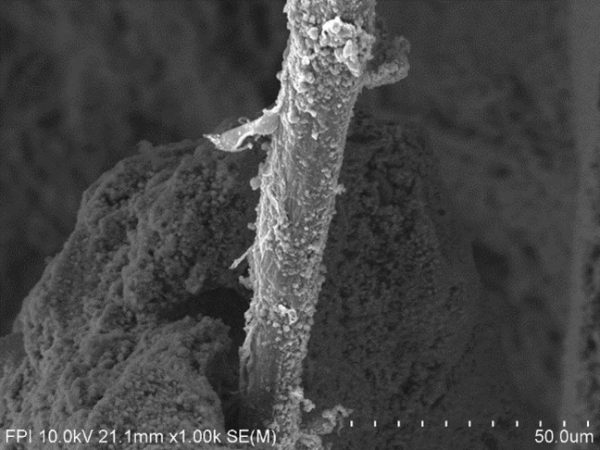

Micrograph of a breaking cement paste sample showing cellulose fibre anchored within the cement matrix. (Photo: FPInnovations)

The use of cellulosic bioproducts in concrete has specifically been gaining momentum in recent years. This has led to the emergence of new products across global markets such as cellulose filaments (CF).

“Cellulosic bioproducts hold unique characteristics and properties that make it stand out as a major player in the bioproducts market and that make it a great addition to concrete applications”, says Frederic Lory, project leader at FPInnovations. When derived from sustainably managed forests such as Canada’s, cellulosic bioproducts can be renewable and can reduce carbon emissions of the concrete industry through carbon storage and through reduced greenhouse gas emissions. They are also readily available in volume since they are a byproduct of other forest operations processes, and are easy to handle and transport in large quantities.

Research conducted by FPInnovations and other research groups has found that adding cellulosic bioproducts such as CF as an additive in concrete can be beneficial in many ways:

- Improves the service life of concrete structures (stability at fresh state and freezing and thawing durability)

- Reduces maintenance costs (better durability and longevity of structures)

- Reduces transportation costs since CF can be procured locally

- Economically competitive, compared to other types of concrete additives

FPInnovations’ in-house concrete lab

Measurement of the air content of fresh concrete. (Photo: FPInnovations)

To develop and enhance its expertise in concrete, FPInnovations built a remarkable in-house concrete laboratory that has received widespread recognition and praise from concrete industry players. Here’s why:

- The lab has testing stations for the entire life cycle of concrete: from the first few minutes of its fabrication when mixed, all the way to its end of life.

- The lab is equipped with specialized advanced research and testing tools and machinery (including calorimeter, dynamic mechanical analyzer (DMA), and cement paste rheometer), that are not readily available at standard laboratories.

The lab offers an agile environment for the development of bio-sourced products within the context of concrete production. The synergy between the concrete and the bioproducts laboratories and expertise at FPInnovations opens the door for future collaborations and allows for exciting new ventures.

“Unique within North America, the concrete lab has been a major stepping stone towards the development of new and innovative bioproducts for concrete applications that are market-ready”, adds Lory. In fact, new scientific breakthroughs in CF in concrete research are leading to major and exciting advancements in the field.

Flow table test for mortar mix.

FPInnovations has been at the forefront of CF research with scientists in laboratories in Montreal, Quebec and Vancouver, British Columbia. Researchers continue working towards improving the functionality of CF, and have taken it out of the lab and into production. In fact, FPInnovations’ CF production technology has been commercialized twice: in 2014 in collaboration with Kruger Biomaterials, and again in 2020 in collaboration with Resolute Forest Products.

A bridge between industries

FPInnovations holds a unique position as the bridge between the forestry and concrete industries. It has expertise in bioproducts, newly-acquired expertise in concrete, as well as a complete understanding of supply and production chains.

FPInnovations’ position also allows it to offer a complete and dynamic solution. Its research professionals are able to not just test cellulosic bioproducts in concrete applications, but also modify, improve and adapt the integration approach based on the specific needs. The constant communication and collaboration between FPInnovations and its various partners also ensure faster product innovation and market readiness.

What’s next?

Well, it’s a beehive.

Scientific research is advancing fast, and FPInnovations is actively pursuing industrial solutions in response to new global economic, environmental, and societal needs. FPInnovations is focusing its efforts on creating a comprehensive strategy for the development of sustainable bio-sourced products in concrete applications.

FPInnovations latest research findings are opening the doors to new and exciting opportunities, so stay tuned.

For more information, please contact Frederic Lory, project leader at FPInnovations, at frederic.lory@fpinnovations.ca.

Print this page