Accident Causation Theory – The Entropy Model:…

Accident Causation Theory – The Entropy Model:

To fully appreciate Productive Safety Management by author Tania Mol (Publisher Elsevier-Butterworth-Heinemann), one must first understand the refreshing accident causation theory and definition of risk on which the book is based, called the Entropy Model. The author suggests that there are two types of risk present in organizations. There is residual risk that cannot be completely eliminated and entropic risk caused when systems degrade. Entropy is a measure of disorganization and is defined as “the degradation of a company’s four basic system factors.”

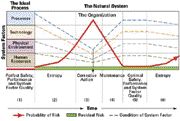

As shown by the Entropy Model included here, they are:

1. Processes (work practices, safe work procedures, business systems);

2. Technology (plant, equipment, tools and chemicals);

3. Physical environment (work site location and structural factors; indoors/outdoors); and

4. Human resources (people).

Every firm uses technology, people and the work site to generate a product or service. These factors interact when a process is undertaken.

Refer to the Entopy Model Diagram;

Section 1: The Perfect or Ideal situation – No accidents and No risk

Section 2: System factors in reality start to degrade (dotted lines), increasing entropic risk (red).

Section 3: Management decides to correct the system deterioration.

Section 4: Future recurrences of this risk have to be prevented using a program of maintenance,

Section 5: Optimum performance – Effective system factor maintenance lifts the organization to a state of optimal safety, performance and system factor quality.

Section 6: If maintenance is not continued, system factor degradation starts again.

Productive Safety Management:

As the book’s title implies, the model demonstrates that safety is good business. If firms allow their systems to degrade, their risk exposure increases and they become less productive. In contrast, well-maintained quality systems allow companies to manage risk, pursue production output and achieve legal compliance and social responsibility. The model provides firms with a balanced, comprehensive approach to managing risk in the workplace and lays the path open for the development of organizational cultures in which production, safety and quality are compatible goals.

Four-Fold Strategy:

The Entropy Model provides organizations with an innovative strategic approach to managing risk in the short and longer term. The methodology, referred to as the Four-Fold Strategy, addresses entropic and residual risks using a multidisciplinary approach. It involves:

1. Taking immediate corrective action to eliminate entropic risk(business/production/safety systems degradation);

2. Establishing (business/production/

safety systems)maintenance strategies to prevent future entropic risk;

3. Managing residual risk in the short term; and

4. Minimizing residual risk in the longer term.

And who should be charged with this responsibility? Why, the Safe Worker of course!

The Safe Worker: A “safe worker” operating in a safety culture, therefore, is defined as someone who:

Is educated about residual risk(hazard management training),

Is vigilant because of residual risk,

Works safely and efficiently to keep entropic risk low,

Is informed of changes in entropic and residual risk, and

Has the knowledge and opportunity to make suggestions that contribute to improved safety, production output and system factor quality.

Conclusion:

The author targets high risk industries such as mining and construction, amongst others. However, this book procedes logically and systematically to define and explain in detail, supported by hundreds of practical suggestions and realistic examples, the steps to preparing for and implementing a Productive Safety Management Plan in any enterprise. The book is a very ‘easy read’ and can be understood by anyone, at any level of a corporation. It can be compared to a lunchtime cafeteria conversation. The author does not talk down to the reader. I have been involved in the development, implementation, maintenance and auditing of OHS Management Systems for over 20 years and this is one of the most down-to-earth, simple, yet comprehensive books on the subject I have ever read. It is well worth the price(approximately $60-$70 CAD) and has to be read from cover to cover to discover the wealth of practical tips and valuable examples that are the glue for assembling and then holding a top OHS management system together. Global safety management thinking is now shifting towards cultivating positive workplace cultures that deal with residual risk and achieving tolerable risk, as opposed to total risk elimination which is considered to be not only impractical, but virtually impossible to achieve. This is the right book for the right times!

John E. Little, Safety Optimisation Technology, can be contacted at jelittle@oricom.ca

Reviewed By John Little

Print this page