Pindo Deli in Karawang, Indonesia, converted a standard rubber-covered suction press roll on PM 5 to Voith’s SolarSoft polyurethane cover. The SolarSoft cover has a suction, blind-drilled, and grooved…

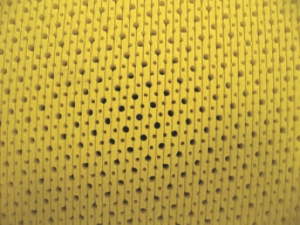

Pindo Deli in Karawang, Indonesia, converted a standard rubber-covered suction press roll on PM 5 to Voith’s SolarSoft polyurethane cover. The SolarSoft cover has a suction, blind-drilled, and grooved surface design, with 45.6% open area compared with 29.57% on the previous roll. “The improvement of open area significantly improved the dewatering capacity and has immediately led to a 5 to 20% increase in machine speed dependent on the tissue grade,” explains Usep Saepul, production manager PM 5. “This change is a major move forward leading to a production increase of between 5 and 12.7 tons per day.”

SolarSoft is the latest generation in polyurethane covers of the Voith Paper Rolls Solar series. It is specially developed for suction rolls and pressure rolls of tissue machines.

The first results clearly show that the machine speed, output, and felt life can be increased, along with significant improvements in tissue quality. In addition, the high tear resistance and elasticity of SolarSoft provide high operating safety and machine availability.

Voith Paper Rolls Division 613-632-4163, www.voithpaper.com

Print this page