Features

Pulp

Water & Chemicals

Technical paper: Kappa number variability during kraft pulping

May 30, 2023 By Augusto Quinde

Kraft digester operators control their cooking operations either by monitoring Kappa numbers (i.e., Kappa target) and/or by controlling digester levels. The most important responsibilities of a digester operator are to produce good pulp quality and to keep the wood chip column moving.

In order to attain stable and uniform cooking operations most or all of the wood chips must go through the same chemical and energy treatment; otherwise, the result will be an unstable cooking that may result in several problems including higher reject levels, lower yield, bleachability issues, poor pulp quality, etc.

A Kappa number controls the cooking degree by measuring the amount of lignin that is left in the pulp after going through the digester or after the different bleaching stages. This very important pulping parameter can be used not only to measure the cooking degree but also to predict the quality of the final products (i.e., pulp, paper).

Kappa numbers can measure the quality of a cooking process and usually is the only parameter measured on-line (Rantanen 2006).

A very common problem for pulp producers is to supply a uniform pulp of high standards that would minimize variations and extra problems during downstream operations (i.e., bleaching chemical charges) or pulp or paper machine runnability issues (i.e., breaks frequency). The production of a consistent high-quality pulp is a great challenge for digester operators due to the complex nature of the delignification process and the crucial residence times in the different zones of a continuous digester.

The main goals of a kraft pulping process are uniform delignification (i.e., low Kappa number variability), high cooking yield (i.e., lower reject levels), high pulp quality, high screen room efficiency, and low recovery load (i.e., organic & inorganic). All these goals can be achieved only if the mill can secure high-quality wood chips, high-quality white liquor and a stable digester control strategy.

Sources of Kappa number variability

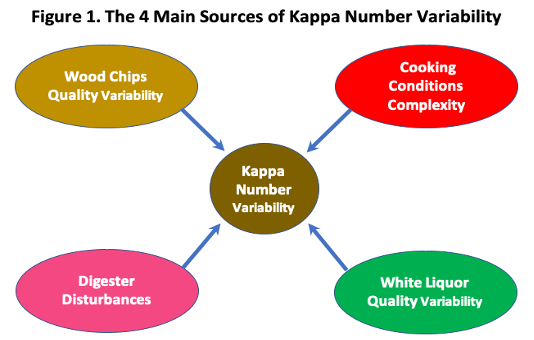

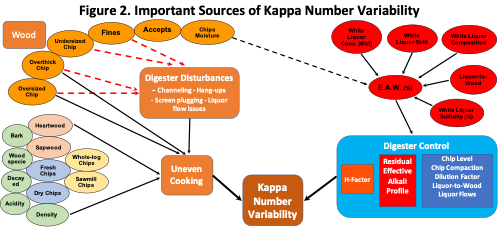

Kappa number variability is a big concern in the pulp production business and there are a few sources causing this variability. The four main sources of this variability are: Wood chips quality variability, white liquor quality variability, cooking conditions complexity and digester disturbances (See figures 1 & 2).

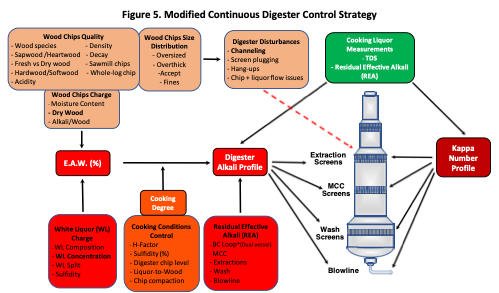

On a continuous digester the pulping parameters to monitor closely are wood chip quality (i.e., chips size distribution, chip thickness, moisture content, fresh vs dry chips); Liquor-to-Wood ratio; alkali charge (i.e., EAW, AA and EA percentages, white liquor concentration); white liquor split addition; digester alkali profile in g/l or lb/ft3 (i.e., in the upper cooking zone, lower cooking zone, extraction zone, blowline residual alkali); Kappa number profile; H-Factor, sulphidity percentage, etc. These parameters need special and close attention in order to secure a uniform kraft pulp (See figure 2).

Wood chips quality

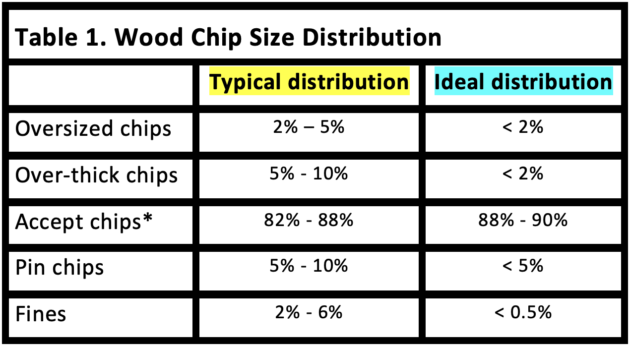

When looking at the quality of the wood chips (i.e., variability) the wood chip size distribution and the moisture content seem to be the variables that need special attention; however, the wood chip size distribution is perhaps the most important variable with regard to wood chip quality. In some countries, the chip size distribution is the basis for payment of sawmill chips, for control of chippers and for monitoring the wood chips for digesters. A mill having the proper chip screening system might show close figures as those expected in an ideal wood chip size distribution (See Table 1 and figures 2, 3 & 5).

When pulping a whole log, one must consider its wide range of wood densities, pH, lignin contents, moisture content and so on. Thus, even pulping only one wood species, the resulting pulp is not expected to be uniform due to the different chemical and physical characteristics. This explains the non-uniformity of the kraft pulping process (i.e., production of rejects, Kappa number variability, etc). If two or more wood species are used for pulping, then the number of variables will increase accordingly.

White liquor quality – Alkali charge and residual effective alkali

When working with continuous digesters, it is important to monitor the residual effective alkali from top to bottom of the digester using an alkali profile control strategy to get a more stable reading of the digester alkali profile. Online control of the residual effective alkali at a few points will help to reduce the variability of the effective alkali throughout the digester to give smoother digester operations and to reduce the Kappa number variability, therefore reducing over-cooking or undercooking (See figures 2 & 5). It seems that a residual effective alkali profile dictates the quality of the pulp and of the black liquor. Pulp quality and black liquor composition are intimately related (Quinde 2019).

Modern white liquor plants must generate a high and consistent quality of white liquor in order to produce an optimal pulp quality and to avoid fluctuations/disturbances in the digester. (Quinde 2022).

Digester disturbances, wood chips quality and Kappa number variability:

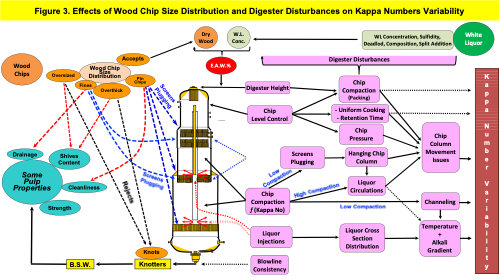

Most continuous cooking digesters are working above their original design by almost 50 to 60 percent, and the most difficult task for the operators to maintain the digesters running is to keep the chip column moving. Frequent disturbances in chip column movement can cause problems in the digester to achieve stable operations that can result in Kappa number variability, channelling, blow line consistency variations and problems with the chip level control (Valmet 2014). See figures 2,3 & 5.

Chip compaction – Channelling – Screen plugging

Chip compaction or packing of the chips, increases towards the bottom of the digester as a function of the Kappa number, the production rate, the chip level, dilution factor, and, to a minor degree, the liquor-to-wood ratio. At lower Kappa numbers the void volume between the wood chips is reduced and they are more easily compressed. Then, at high Kappa numbers occurs the opposite and the digesters can be taller than low Kappa digesters without developing excessive compaction.

In cases where the compaction is too low, there are two scenarios: a) the wood chips can be pulled from the chip column into the screens and ultimately plug them; and b) there is a risk of channelling through the chip column. However, if the compaction is too high, the channelling can be along the digester walls. Channeling is a very common disturbance in a continuous digester that contributes to variability of Kappa numbers (Valmet 2014, Jansson 2009). See figure 3.

As per Puolakka and Kortela (2005), the chip compaction is an important factor to control the cooking process and the quality of the pulp. When knowing the chip compaction in the digester then the disturbances in the digester are easier to identify and rectify.

Chip column movement

Uneven wood chip size distributions contribute to poor cooking conditions and a variable pulp quality. Pin chips tend to plug the void between chips, causing a higher flow resistance in the chip bed. Reduction in the overall percentage of undersized chips (See Table 1) in the digester feed improved the circulation rate and increases yield by reducing overcooking of undersized chips (Quinde 2020).

If there is a slow movement of wood chips along the digester walls, then the result is a poor wiping of the digester screens and consequently a strong contribution to screen plugging. Then, later, when the chips near the digester walls come out, they must be over-cooked, giving large Kappa number swings at the blow line.

Liquor circulation is the appropriate way to add the liquor(s) to the digester, which affects the temperature uniformity at the periphery (i.e., circumferential temperature gradient). Furthermore, uniform distribution of filtrates influences chip column and liquor flow patterns in the different zones of the digester. Channeling flow of chips and/or liquor affect the variability of some pulping parameters (i.e., residence time, cooking chemicals profile and temperature profile when passing through the different zones in the digester, resulting in higher reject levels and lowered screened yield.

Reducing the proportions of undersized wood chips in the digester feed must improve the liquor circulation rates and also increase the pulp yield by reducing overcooking of undersized chips. This reduction can help to shrink the white liquor application and, in turn, reduce the load in the recausticizing area.

Digester chip level

A steady digester chip level secures an optimum chip pressure, chip compaction and chip column movement in the digester. The downward velocity of the wood chips changes through the digester due to a few factors: liquid flow, degree of delignification, the height of the chip column, and the liquid level in the digester.

Daily average Kappa numbers versus daily range Kappa numbers – Softwood cooking – Bleachable grade

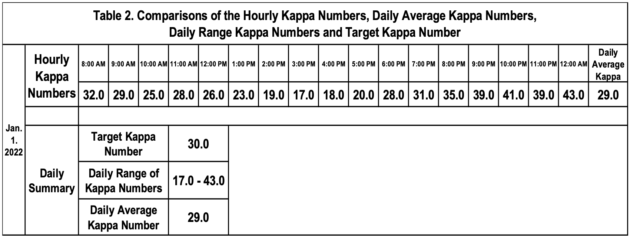

Most kraft pulp mills submit (i.e., technical mill meetings) their digester Kappa numbers usually as the daily average figures. Using daily average data is misleading as explained in the following example for Jan.1.2022 (See Table 2)

The Kappa number average for Jan.1.2022 is 29 and is very close to the target Kappa number of 30. When comparing the daily averages versus the target Kappa number there is not too much differences between them and it would be assumed that the digester is performing very well. However, the hourly Kappa numbers data (Table 2) show a serious variability with a minimum Kappa number of 17 (i.e., 3:00PM) and a maximum of 43 (i.e., 12:00AM) that equates to 26 Kappa units difference for that day showing a “poor” cooking operation of this digester. The hourly Kappa number distribution shown in Table 1 can be observed almost every day in some kraft pulp mills. This variability can be correlated with pulp quality and strength (Albadvi 2010).

The daily or monthly average Kappa numbers do not reflect the high variability observed in the hourly data. When running an audit of cooking operations (i.e., continuous or batch digester) a very important parameter to evaluate is the Kappa number data that should include: hourly figures and target Kappa number. See figure 4.

Low Kappa numbers versus high Kappa numbers (i.e., Softwood cooking – Bleachable grade)

Low Kappa numbers (24-25) or very low (17-18) may indicate that the cooking has been forced drastically and that the effects of this situation would be: a) lower pulp yield (Esteves at al. 2021; Segura et al. 2016), b) losing pulp strength, c) generating too much black liquor solids (BLS) that would affect black liquor carryovers, d) higher and/or inaccurate chlorine dioxide (ClO2) charges, etc.

“High Kappa number digesters can be taller than low Kappa number digesters without developing too high a compaction factor” (Valmet 2014).

Effects of low and high Kappa number in a kraft mill

Some of the effects of low and high Kappa numbers are shown in Table 3.

How to reduce or minimize Kappa number variability

It is very common to hear that the white liquor concentration changes every 2 hours, or that the sulfidity changes every 5-7 hours, or that there are channeling issues every 12-18 hours, etc, etc. However, there is no information on how the wood chip quality going to the digester is changing. There is little or no information going to the digester control room about the proportions (i.e., %) of the oversize chips and/or overthick chips and/or fines that are responsible for digester disturbances. The size and the size distribution (i.e., proportions in percentage) of the wood chips is very important not only because of the effects during the pulping operations (i.e., pulp yield, pulp quality, digester operations) but also for the consequences on the post-digester handling (i.e., washing, screening, cleaning and refining) of the pulp (Quinde 2020).

At present, there are a few software applications being offered that would help Kraft pulping digester operators to monitor white liquor parameters (i.e., concentration, sulfidity, etc) and/or H-Factors (i.e., cooking temperature) and/or the Residual effective alkali profile and/or to use a Predictive Kappa number control and/or Kappa number profile control (Kayihan 1998) and/or Kappa number predictions (Lemmetti 1998), and/or to measure variability within kraft digesters (Albadvi 2010), etc. All these advanced systems will give the digester operators the current levels of the above parameters but because there are so many changes going on at the same time; then, it is almost impossible that a human being would be able to control all these changes. Therefore, a software package (Advanced Process Control) is necessary to predict and/or to correct and/or to control all the pulping parameters. Modelling has been utilized for control purposes of cooking degree in conventional and modified continuous pulping processes (Rantanen 2006, Rantanen et al. 2005, Rahman et al. 2018, Jansson 2009).

As per Fairbank (2019), process variability can be originated by a number of causes that might include raw material variation (i.e., wood chips quality), grade changes and/or human factors. Implementing an Advanced Process Control (APC) application can minimize the variability of key pulping parameters (i.e., Kappa number) by applying a combination of predictive control and pulp tracking techniques. When producing off-spec pulp for 10 minutes at the digester, then, the system can predict when the bad pulp will reach the various downstream operations (i.e., bleaching). These systems help in taking corrective actions before the damage is done as opposed to conventional controls that react after off-spec quality is detected. When using an advanced process control (APC) in a continuous digester the following variables can be controlled: Kappa numbers, Residual effective alkali, digester chip levels, blow consistencies, etc. Then, implementing an APC application can minimize Kappa number variability.

As per Lampela et al. (2019), cooking is a very complex or highly interactive process that requires a close and sophisticated control. Furthermore, they me

ntioned that “Kappa number and residual alkali measurements provide an accurate estimate of pulp yield and with enhanced control of delignification and alkali profile, the mill can increase pulp yield while maintaining steady blow Kappa level.” See figure 5.

It is very common to have a remarkable product quality variability even with good Kappa control (Kayihan 1998). A pulp mill can have a very sophisticated control (i.e., Kappa profile control, APC applications, etc) but if the wood chip size distribution is poor, then digester disturbances (i.e., chip column movement, channeling) can result in Kappa number variability.

Before considering the whole list of pulping parameters that needs a close control and monitoring for getting reliable kappa numbers, it is essential to emphasize the different results that can be obtained when relying either on the operator control (i.e., risky option) or by using a computerized online system for this monitoring (i.e., reliable or necessary option).

References

- Albadvi, E. (2010) “Measuring Uniformity in Kraft Digesters Using Flow-Following Sensors”. M.Sc. Thesis. The University of British Columbia, Vancouver, Canada. 84 pp

- Andrews, J.D. and Hart, P.W. (2013) “Improving pulp yield for integrated southern hardwood kraft mills – significance and impact on chemical recovery, steam and power generation and bleaching”. TAPPI Journal 12(2):41-53.

- Colodette, J.L., Gomide, J.L., Junior, D.L., and Pedrazzi, C. (2007) “Effect of pulp delignification degree on fiber line performance and bleaching effluent load”. BioResources 2(2): 223-234.

- Esteves, C.V., Sevastyanova, O., Östlund, S. and Brännvall, E. “Differences and similarities between kraft and oxygen delignification of softwood fibers: effects on chemical and physical properties”. Cellulose 28: pp 3149–3167 (2021).

- Fairbank, M. (2019) “Taking Control of Variability in the Pulp Mill”. Pulp & Paper Canada 120(4):18-19.

- Jansson, J. “Digester modelling for diagnostics and control”. Doctors’ Thesis. Mälardalen University, Västerås, Sweden. 86 pp (2009)

- Kayihan, F. “Kappa Number Profile Control for Continuous Digesters”. In: Berber, R. and Kravaris, C. (eds) “Nonlinear Model Based Process Control” pp 805-829. Springer, Dordrecht. Available at: https://doi.org/10.1007/978-94-011-5094-1_26

- Lampela, K., Zuver, D. and Carwile, D. (2019) “GPI West Monroe digester optimization project”. TAPPI PEERS. Pulping.Engineering.Environmental. Recycling. Oct.27-30, 2019. Valmet Inc. and Graphic Packaging Intl. collaborated project. pp 9. Available at: https://www.tappi.org/content/Events/19PEERS/19PEE11.pdf

- Lemmetti, A., Leiviskä, K. and Sutinen, R. (1998) “Kappa number prediction based on cooking liquor measurements”. Technical report: A No 5, May 1998. Control Engineering Laboratory, University of OULU, Finland.

Print this page