News

Products

Equipment & Systems

Tissue

Toscotec introduces concept machine for sustainable structured tissue production

July 5, 2022 By P&PC Staff

Photo: Toscotec

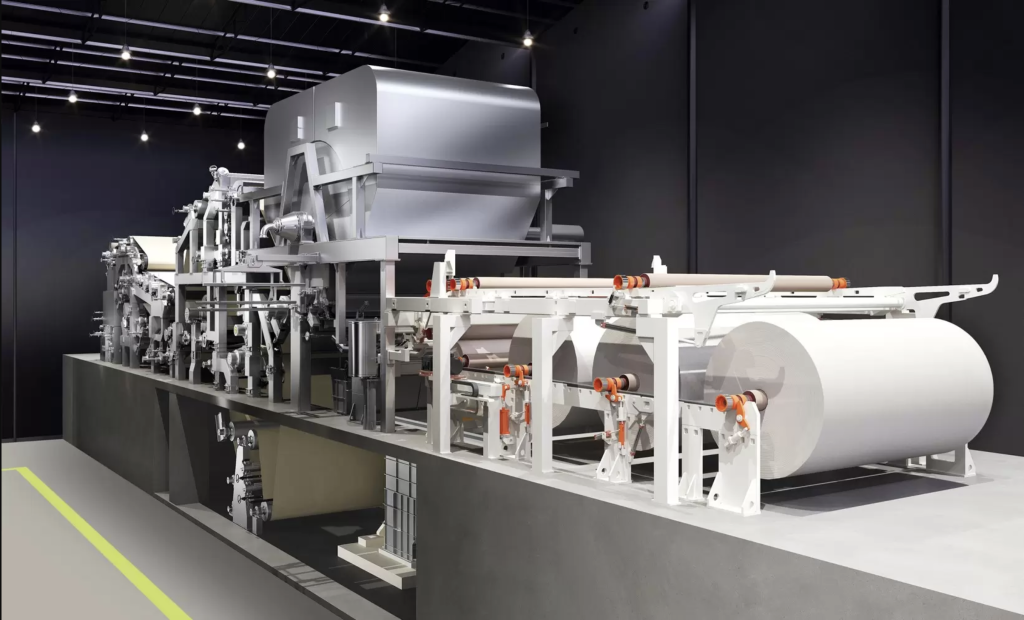

Photo: Toscotec Toscotec launched a new concept tissue machine designed to produce high-quality structured tissue paper – Ingenia.

According to the company, tissue quality generated by Ingenia is higher than textured tissue and close to Through Air Drying (TAD) produced paper, but it uses 35 percent less energy.

With Ingenia, Toscotec aims at catering to the demand in the market for premium quality tissue obtained with lower energy use and lower capital investment than TAD lines. Ingenia’s concept is based on consolidated technologies for premium tissue. It is built by leveraging the internal knowledge of Toscotec’s and Voith’s R&D and field data validation on TAD and structured paper systems.

Ingenia produces high tissue quality properties through non-compressive water removal technologies and efficient fibre moulding. These properties include bulk, softness, stretch and absorbency. The specific pattern of the structured fabric and the use of a calender can further enhance the quality of end products.

The process of this new concept machine begins with a dilution profiling layered TT Headbox-ML operating on a twin-wire forming section. Like TAD machines, Ingenia operates wire rush transfer at low consistency. It uses an enhanced vacuum de-watering system without pressing the paper web, which ensures that dryness is increased while fibres are being supported in the same shape as they originally formed when fully water-saturated.

At the end of the wet section, TT NextPress shoe press uses low loading pressure to gently stabilize the web dryness content and transfer the paper to the drying section without bulk compression. The combined action of a third-generation design TT SYD Steel Yankee Dryer and high-efficiency TT Hood achieves the final desired dryness.

The process is completed by dry creping, sheet stabilization integrated with dust removal and precision winding using an electro-mechanical TT BulkyReel fitted with a Center Wind Assist on the primary and the secondary arms. The Center Wind Assist preserves bulk by reducing the nip pressure against the reel drum during the winding process.

The new Ingenia can swing from the production of premium quality structured tissue to conventional DCT. Ingenia features widths up to six metres, a production capacity from 100 to 250 tpd and operating speeds up to 1,500 m/min in structured tissue mode or 2,000 m/min in conventional mode, depending on machine size and customer requirements.

Print this page