News

Products

Equipment & Systems

Maintenance & Reliability

Software

Valmet introduces reliability monitoring tools to for enhanced predictive maintenance

July 11, 2022 By P&PC Staff

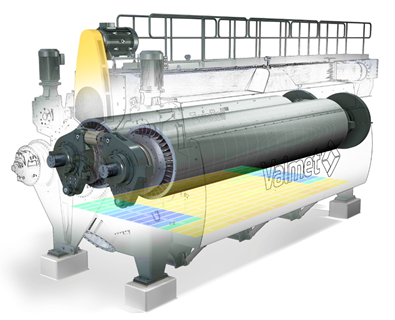

Photo: Valmet

Photo: Valmet Valmet recently launched new reliability monitoring applications for fibre processing equipment to enhance predictive maintenance.

The applications are part of the Valmet Industrial Internet offering. They provide tools to fibre producers to secure equipment availability and to improve process performance. The monitoring system combines modern sensor, signal processing and data transfer technologies applied to fibre production processes.

One of the first commercial applications is Valmet TwinRoll Press Vat Temperature monitoring. The application monitors pulp flow distribution inside the press through temperature measurements and visualizes, for example, the situations when the press gets plugged and pulp flow is disturbed. This application can be used as a standalone input to monitor press plugging or it can be connected to Valmet’s extensive TwinRoll Press performance monitoring systems to secure the overall reliability and washing efficiency of the press.

Another new application is Valmet Feeder Rotor Position Monitoring. To maintain an optimal steady-state in the continuous cooking process, low- and high-pressure feeders must provide a stable chip flow in the digester feeding line. The monitoring system visualizes feeder adjustments, identifies impending problems and supports operators with accurate adjustments for successful chip feeding.

Valmet reliability monitoring applications can be installed as a standalone device for single equipment monitoring.

Print this page