Products

Maintenance & Reliability

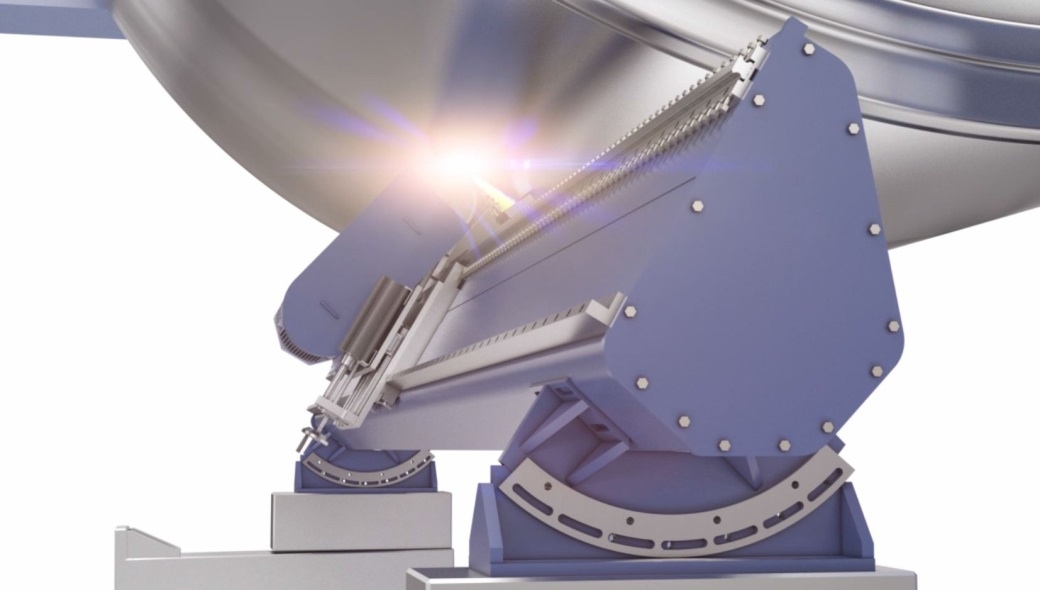

Voith MiniGrinder boasts precise removal of surface irregularities

May 5, 2017 By P&PC Staff

May 5, 2017 – The MiniGrinder, developed by Voith’s OnSite Yankee Service, promises to enable the “easy and accurate” removal of surface irregularities, old coatings and chatter marks.

The MiniGrinder’s compact design allows for it to be used on any tissue machine without the need to remove and re-install key machine parts, as is normally the case with conventional grinding machines, says the company, adding that this reduction in maintenance time leads to quicker restart time. One Voith customer even reported a 14-hour reduction of downtime. Voith says the grinding force of the head is equivalent to that of conventional tangential grinding heads, boasting maximum precision for all types of applications. The MiniGrinder is suitable for all kinds of metal surfaces. The exhaust air system used with the MiniGrinder removes the airborne dust that occurs during the grinding process, which Voith says helps to reduce the cleaning effort while protecting the health of personnel working on and around the Yankee cylinder.

Print this page