Features

Paper

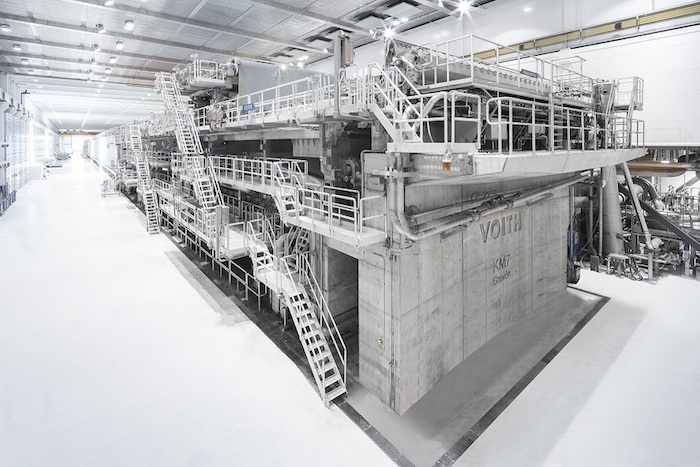

Voith supplies largest board machine to BillerudKorsnäs

August 6, 2019 – BillerudKorsnäs recently commissioned KM 7, the largest board machine in the world, at its production facility in Gruvön, Sweden.

August 6, 2019 By P&PC Staff

Voith's XcelLine board machine KM 7 for BillerudKorsnas produces four different board grades.

Voith's XcelLine board machine KM 7 for BillerudKorsnas produces four different board grades. The Voith XcelLine board machine started up on June 28, 2019 and has been equipped with a technological setup that sets new performance benchmarks for production lines for four different board grades. At a design speed of 1,200 m/min and web width of 8,800 mm, the capacity of the KM 7 is 550,000 metric tons per year. Start-up took just seven days from stock on wire to paper on reel.

“We were able to meet all major milestones and have been producing high-quality liners for our customers on the KM 7 since the end of June,” says Maria Engnes, program director of NEXT Generation at BillerudKorsnäs. “We will continue to focus on the successful start-up of the KM 7, safety, production stability, efficiency improvements and innovation.”

State-of-the-art features

Some of the standout features of the former section include a three-ply wire section with a DuoFormer D II hybrid former, two state-of-the-art DuoShake shaking units and a fibre orientation control system. The scope of supply also includes various MasterJet Pro F systems with additional IntraDamp modules for the headbox. In the press section, a Tandem NipcoFlex shoe press with SolarPress roll covers ensures optimum dewatering.

In the dryer section, EvoDry steel cylinders are being used in a board machine for the first time. The special cylinders allow highly efficient and safe paper drying thanks to higher heat transfer and greater working width. Another first at a European paper mill is the winder VariFlex Performance.

In the finishing section, the KM 7 is also the first board machine worldwide to be fitted with curl control. The machine also has four different coating units: two SpeedSizer AT systems, one JetFlow F and one DynaCoat AT. Both the SpeedSizer AT units and the DynaCoat AT have carbon-fibre supporting structures to ensure stable CD profiles with consistent coating performance.

Integrative digital solutions

Voith’s Papermaking 4.0 solutions OnEfficiency and OnCare, which allow all process data to be monitored and controlled online in a user-friendly format, are also major components of the KM 7. Among other things, OnEfficiency Forming enables dewatering, retention and flocculation to be stabilized and coordinated at the same time. The OnCare package including integrated asset management ensures maximum machine availability thanks to highly efficient preventive maintenance of the entire paper machine. This in turn also helps reduce project costs.

Initial clothing

Voith was engaged to supply the initial clothing for the KM 7. In addition, as main supplier for the BillerudKorsnäs mill, Voith will over the next three years supply the CleanWeave dryer fabrics, Kinetic and Infinity press felts and I-Series forming fabrics.

Print this page