Features

Health & Safety

Paper

Pulp

Workforce

2021 Safest Mill in Canada winners announced

June 7, 2022 By Sukanya Ray Ghosh

Resolute Thunder Bay used digital tools during the pandemic to provide safety training. Photo: Resolute Forest Products, Thunder Bay

Resolute Thunder Bay used digital tools during the pandemic to provide safety training. Photo: Resolute Forest Products, Thunder Bay Pulp & Paper Canada has been benchmarking the safety performance of mills since 1926. The COVID-19 pandemic has significantly changed safety protocols in the industry over the last two years. While the world tries to get back to functioning normally, many of the changes are here to stay permanently. 2021 was the second year that saw pandemic-related safety restrictions in the workspace.

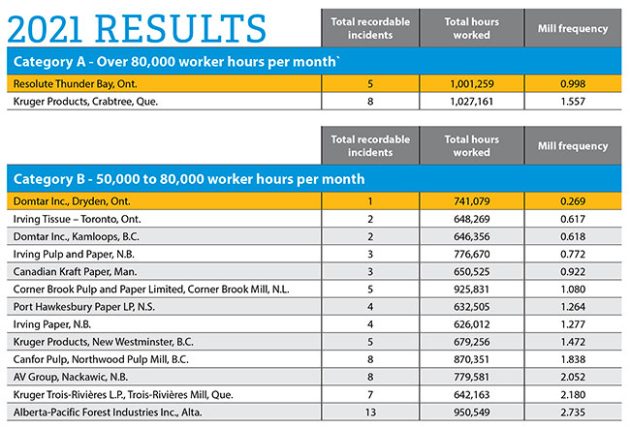

The annual Safest Mill in Canada contest recognizes the outstanding safety records of participating mills by ranking total recordable incidents (mill frequency) from lowest to highest. In the event of ties, mills are ordered by the most to least worker hours. Congratulations to all participating mills for staying at the top of their safety goals and achieving success.

This year, Resolute Thunder Bay bagged the top place in Category A.

Congratulations to them and to all of our participating mills for committing to safe practices in 2019!

Find the winners below and the full list in our Spring 2022 issue.

CATEGORY A (Over 80,000 worker hours per month)

Resolute Forest Products, Thunder Bay, Ont.

Total recordable incidents: 5

Total hours worked: 1,001,259

Mill frequency: 0.998

CATEGORY B (Between 50,000 to 80,000 worker hours per month)

Domtar Inc., Dryden, Ont.

Total recordable incidents: 1

Total hours worked: 741,079

Mill frequency: 0.269

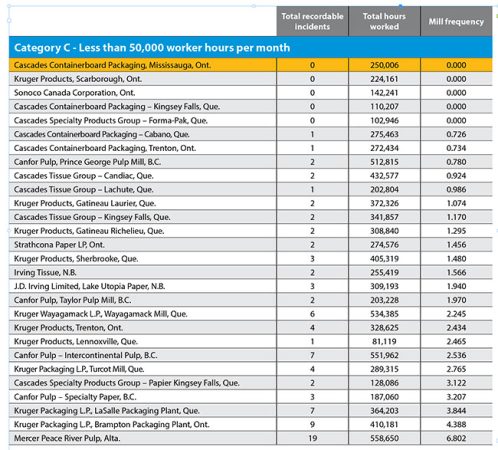

CATEGORY C (Less than 50,000 worker hours per month)

Cascades Containerboard Packaging, Mississauga, Ont.

Total recordable incidents: 0

Total hours worked: 250,006

Mill frequency: 0.00

See the full list of 2021 Safest Mill in Canada winners in our Spring 2022 issue.

To participate in the 2022 contest, email me for rules and reporting forms.

In conversation with Resolute Forest Products’ Thunder Bay mill

In conversation with Resolute Forest Products’ Thunder Bay mill

Pulp & Paper Canada: What makes your safety system successful? How do you achieve success?

Resolute Forest Products, Thunder Bay: A successful safety system is not achieved by accident; it requires rigour, accountability and engagement. Active management commitment and employee involvement are key to ensuring a safe, injury-free workplace. Resolute’s safety management system is comprised of three pillars that drive our everyday focus on health and safety: one-on-one safety commitment discussions, hazard recognition and near-miss reporting.

P&PC: What has been the top safety priority at your mill for 2021? What are the major highlights from the year?

RFP, Thunder Bay: Keeping our workers safe is always a top priority. In 2021, Resolute achieved a world-class company-wide OSHA incident rate of 0.47, despite the pandemic and other challenges. At the Thunder Bay mill, our safety focus last year included guarding, hazard awareness and training our workers to methodically approach tasks by using our ‘7 Prevention Reflexes’ program. Employees go through a series of questions to evaluate potential risks and hazards related to a job or task, allowing them the time to re-evaluate and approach a job or task differently if needed.

P&PC: How has the pandemic impacted safety programs in your mill?

RFP, Thunder Bay: The COVID-19 pandemic prompted the mill to quickly adopt more digital tools for reporting and communicating. Many of these digital tools and options have now been integrated into the site’s safety management system. A good portion of our training has been provided virtually since the outset of the pandemic, and this will probably continue to allow for flexibility in terms of schedules.

P&PC: What are your safety plans for 2022?

RFP, Thunder Bay: The site’s 2022 goals include improvements in the area of communications, training around root cause analysis and troubleshooting and preparing to pursue official ISO 45001 certification. We will also focus on the continued rigour of task-based audits at the supervisory level.

P&PC: How do mill employees respond to Resolute Thunder Bay’s health and safety mandates?

RFP, Thunder Bay: We have empowered our employees through near-miss reporting. This platform allows employees to report all issues, no matter how big or small, which are then reviewed by management daily. Each near miss is expected to be acknowledged by management within 48 hours so that a response can be provided. We have also involved many of our workers in the ongoing update of work instructions and standard operating procedures. By involving employees from the beginning through to the implementation stage, we can ensure that what we are releasing is relevant to the various jobs and tasks we have at the site.

Print this page