Features

Paper

Pulp

Tales of transition: AV group’s story of growth and success over the years

June 6, 2023 By Sukanya Ray Ghosh

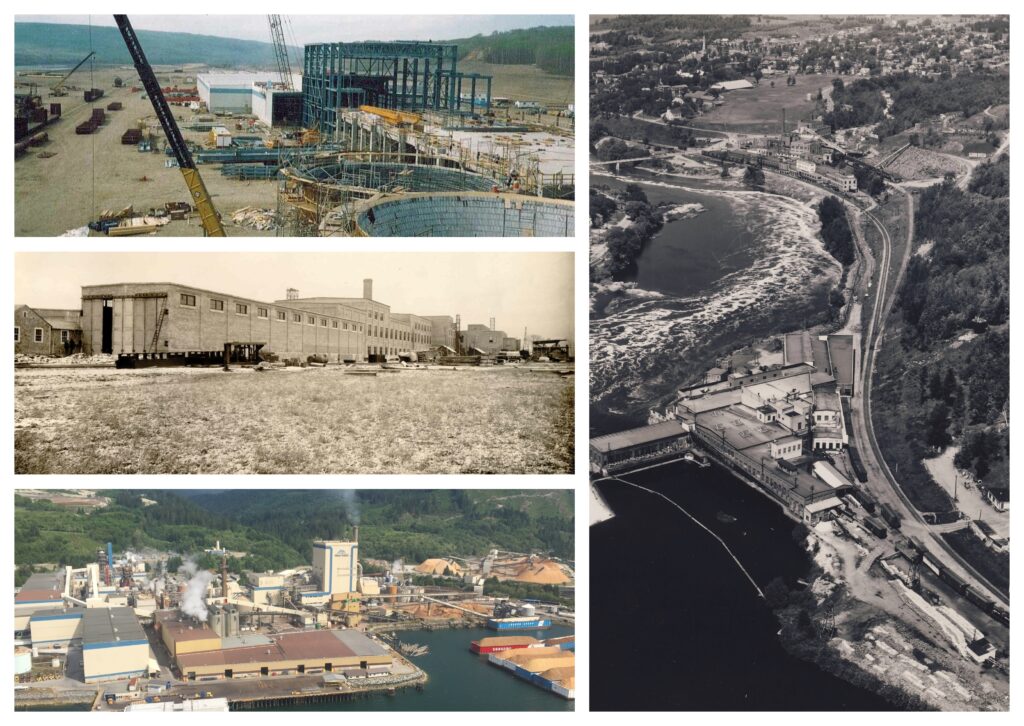

Photos by Mercer International (top left), Kruger (middle left), Paper Excellence (bottom left) and Domtar (right).

Photos by Mercer International (top left), Kruger (middle left), Paper Excellence (bottom left) and Domtar (right). A major contributor to the Canadian economy, the pulp and paper industry has endured through years of drastic changes in the market. It was a leading global producer of newsprint paper once upon a time, as well as a major pulp producer. With the evolving times, Canadian mills have embraced the needs of the hour. Today, the focus is on pulp and paper alternatives to plastics, packaging products for the highly demanding e-commerce industry and adoption of sustainable practices.

In this special anniversary feature, five stakeholders of the Canadian pulp and paper industry share how they have evolved and their vision for the future.

This is AV Group’s story of growth in Canada.

AV Group’s journey in Canada started with the acquisition of an NBSK mill in Atholville, New Brunswick in 1998. The Atholville Mill was originally built in 1930. On taking charge, the AV Group converted it from an NBSK mill to a dissolving grade pulp mill. The group later acquired a comparatively newer kraft mill in Nackawic, N.B. in 2005. The Nackawic mill originally produced photographic paper, with Kodak as one of its main customers. The group converted the operations at this mill to dissolving grade pulp in 2008. The Terrace Bay Mill in Ontario was the third Canadian mill to join the AV Group, purchased in 2012. The mill produces NBSK pulp for the tissue and graphic paper markets.

The escalating energy costs have been posing a challenge for mill operations in recent years, notes Mike Legere, director of government relations and communications at AV Group Canada. As a result, the mills have sought investment to be more self-reliant on energy production, and investment in power boilers and steam generation, adds Legere. Another recent shift in the industry that impacted mill operations in the past few decades, says Legere, is effluent regulations. He explains that the industry as a whole is working hard to meet the current requirements. In the context of sustainability, Legere says that dissolving grade pulp needs different types of certifications when it comes to wood procurement and sourcing. These factors, combined with the industry’s focus on sustainability have impacted the operational decisions at AV Group’s mills.

The AV Group, which is celebrating its 25th anniversary in Canada this year, is embracing technology to drive growth. It has implemented automated processes in its mills to reduce costs and improve efficiencies. Legere shares that the group is looking at full digitalization of the mills, as well as the woodland operations.

“It speeds everything up. It permits the collection of big data. And data will allow us, in the future, to implement artificial intelligence so that we can predict and address issues before they happen,” says Legere.

This is paramount in the pulp business to address reliability issues and prevent cost escalations.

Legere says that the AV Group is no more just a pulp and paper business. It is now in the biorefineries business as well. The focus, he says, is now on how to derive full value from the wood. The group’s facilities produce different grades of dissolving pulp that have applications beyond the pulp and paper industry.

Legere says that resiliency comes from the ability to pivot. The AV Group has been able to successfully adapt to changing market trends and conditions and will continue to do so in the future.

Read the stories of other major industry stakeholders here:

Print this page