News

Products

Paper

ABB announces the launch of its new sheet break detection device

April 25, 2022 By P&PC Staff

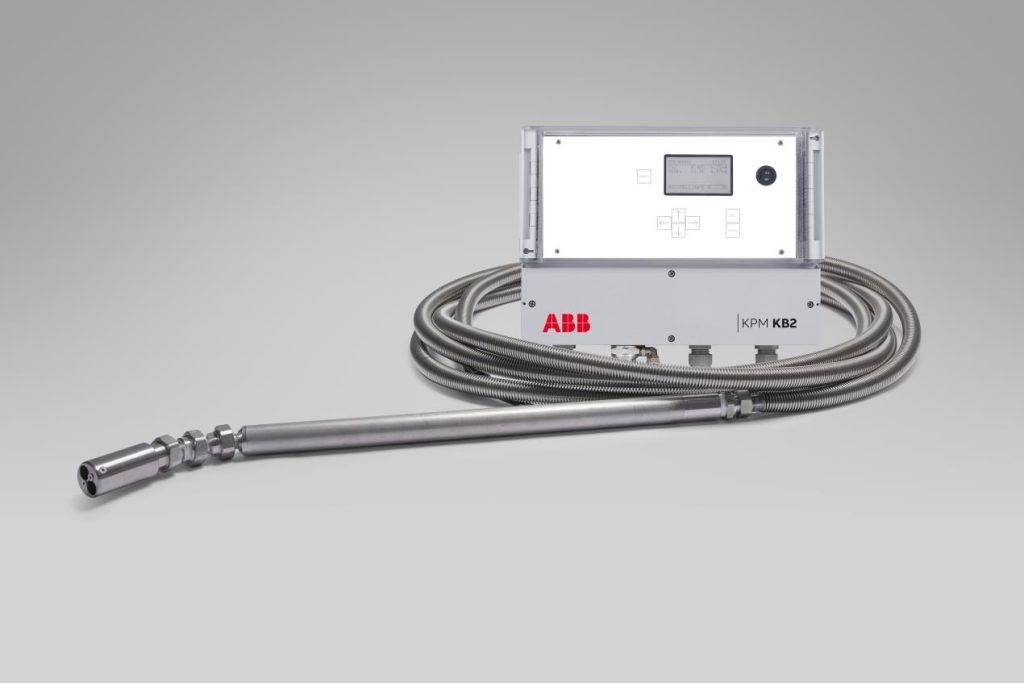

The KB2's electronics unit is mounted outside the machine hood using fibre optic. (Photo: ABB)

The KB2's electronics unit is mounted outside the machine hood using fibre optic. (Photo: ABB) ABB announced the launch of its new KPM KB2 Ranger Model, a sheet break detection device. According to the company, the device is invulnerable to paper jams, colour and grade changes.

The latest addition to ABB’s industry-leading KPM Sheet Break Detector portfolio, this non-contact optical sensor is designed for paper or board producers making frequent grade changes or coloured papers. It features a single, one-button calibration. The RGB break profiling method reduces false positives and automatically updates for more robust detection over time.

The KPM KB2 Ranger model offers a measurement distance of up to 1.5 meters. Side installation keeps the sensor head outside the machine. It can provide break detection in all configurations, such as against felt, wire or cylinders, and its freely adjustable sensor head detects breaks from any angle. This removes the possibility of paper getting stuck on the sensor head.

While the sensor head can withstand high temperatures, the electronics unit is mounted outside the machine hood using fibre optic cables, preventing the electronics from being affected by dirt, steam or temperature.

ABB’s KPM KB2 Ranger model requires minimal maintenance and cleaning due to its air-purged sensor that keeps the unit clean for continuous and trouble-free operation.

“Our KPM Sheet Break Detector is recognized as the best on the market and the proven choice for installations in harsh environments or where space is limited,” said Karin Hermansson, product line manager at ABB. “We are pleased to unveil the new KB2 Ranger Model to offer additional options for mills facing frequent grade changes or colour-related issues while proving our commitment to continual innovation surrounding mill optimization solutions.”

KB2 is applicable globally across paper, tissue, board and pulp machines and can be used on press or drying sections.

Print this page