Features

Paper

Q & A

Women in Forestry

Workforce

All in the family: Q&A with Laura Pettit, reliability engineer at Canadian Kraft Paper

March 2, 2020 By Kristina Urquhart

Who: Laura Pettit

Role: Reliability engineer

Employer: Canadian Kraft Paper

Lives in: The Pas, Man.

Years in industry: 13

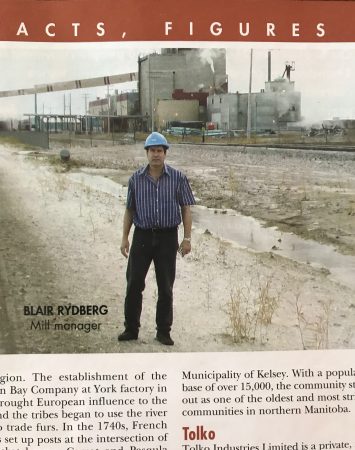

A third-generation forest products worker, Laura Pettit followed in her dad’s footsteps to a career at Canadian Kraft Paper, the former Tolko mill in Manitoba. Fifteen years after her father, Blair Rydberg, was featured in an article in Pulp & Paper Canada, Pettit tells us she was grateful for his guidance as she found her way in the industry.

Pulp & Paper Canada: What is your day-to-day like as a reliability engineer at Canadian Kraft Paper?

Laura Pettit: I am in charge of the quality control programs for pressure systems, so I do a lot of work with the welders and the pipe fitters. I’m also a welding inspector.

I usually take a couple of walks around the mill and look for things that are leaking or not operating properly. I also have about five people that work directly under me – the vibration specialist, the lubrication specialist, and then some of the reliability techs.

We always have a morning meeting onsite. We go through what happened overnight, or what happened yesterday, and then the mill kind of resets its priorities. We might have extra work or some inspections to do based on that, and then part of my day is usually planning for our future shutdowns.

I do some of the defect elimination, so if we have a piece of equipment that’s not running reliably, then we either hold group sessions to discuss why it’s not working, or I’ll try gather more information about how things are running.

PPC: What is the problem that you come up against the most? What’s a challenge that keeps recurring?

PPC: What is the problem that you come up against the most? What’s a challenge that keeps recurring?

LP: One challenge that we have in [the mill] is that it’s getting old! So there is lots of maintenance that needs to be done. We’ve got pipelines that might be original – so they might be 40 or 50 years old. We try to prioritize based on how long things are going to last.

PPC: What’s your favourite thing about working at Canadian Kraft Paper?

LP: I would definitely say the people. I work up in the engineering group, and there’s about 15 of us. I’m the only woman. There’s 14 guys, but we have a really good group. The guys on the floor, I find I’m able to ask them questions. They’re usually really good for giving information or working together.

We always want it to be a better place to work and to make a better product. And the people really care, I think.

PPC: What project have you worked on that you’re most proud of?

LP: The quality control program. I think because we’re kind of out of the way from the major [urban] centres, sometimes people start slacking off on some of the rules we have to follow.

[When I came into this role] I had to try and learn a lot of the process, and lots of it we weren’t doing. Over the past couple of years, we’ve really focused on trying to update our quality control program, and start following the codes a little bit more, and getting the guys on the floor more engaged in it.

It was a lot of work with them [to review] how to try and make it better. Like, how do we improve the process so we’re still following the rules and the codes and the laws, but it’s more streamlined for them?

PPC: What are some strategies you’ve undertaken to do that?

LP: Working with the guys, asking their input – you know, how do you use the forms, things like that.

For example, we stock a bunch of welding rods and I’d asked, why are we not using these [specified] ones, why are we using these other ones that you’re not supposed to be using? And they said the [spec] ones don’t work properly, they cause issues. So okay, let’s look at getting new ones onsite that are to code, but that will work for the guys as well.

I worked a little bit with a consultant who had been other places. I’ve only worked here [at Canadian Kraft] in the pulp and paper industry. So it was good to go back and forth with my consultant and say, well what do other places do? And then I would discuss that with the guys on the floor.

PPC: What excites you about your future and pulp and paper?

LP: I like how when I’m in the job I’m in now, it’s a little bit of everything. You do manage the quality control program, but you do a little bit of project engineering. You do a little bit of supervision – you’re in water treatment, you’re in steam room recovery. So it is really good for getting a little bit of knowledge on a lot of different areas.

In the next couple years, I’m hoping to do a little bit more management. Just from working with the guys on the floor, I’ve found I’ve developed really good relationships. Like I said, I supervise about five people upstairs. We have had a couple supervisor trainings over the past few months, and I’ve been kind of going through some of those suggestions and trying to work on my people skills more.

I also do want to do more on the inspection side of things. I’m a level one welding inspector, and I’m hoping to eventually become a level two. And then I’d also like to get into pressure vessel inspection.

PPC: What drew you to pulp and paper in the first place?

LP: I’m actually a third-generation pulp and paper employee. My dad moved around throughout his career in pulp and paper and then ended up here [at Canadian Kraft].

I got a job here as a summer student in the machine room, and then I met my husband here. So I stayed in The Pas and stayed in this industry. Both of my grandpas were also in pulp and paper. It’s like a Northern thing to get into!

PPC: What did you take in school to prepare for getting into the industry?

LP: I took mechanical engineering at McMaster in Hamilton. My dad [pictured above in a 2005 Pulp & Paper Canada article] was also a mechanical engineer. So he kind of encouraged it – not necessarily to be in pulp and paper but just all the different pathways you can take with it. Just to open the doors.

PPC: Who were your mentors when you started out in the industry?

LP: The guy who did the job before me ended up leaving the company about three years in, but he was my first introduction to the quality control program and doing inspections.

And then I would say my dad. He used to work here, so he helped me a lot as well, just to go through the process. And he was really good with taking me out and saying, okay, this is what we’re looking at. Or, if you want to try and design something, let’s go and see what’s there and how the process works.

PPC: What challenges did you face starting out in your career?

LP: Just being a woman in the industry where there are so many men. I didn’t grow up here, so I didn’t know a lot of the people, either.

I’m more confident now, more straightforward – but when I first started I was a little bit more introverted and shy. That was the main thing to overcome. If I had questions, I just had to start asking them and try to get the information.

I’ve built good relationships with the guys on the floor so when there are problems, we usually try and work it through together.

There are so many people who have worked here for 30 years, 40 years. They have so much experience and so much information and you just have to ask. You just have to talk to them. I probably didn’t know very much when I first started, but I was willing to learn.

PPC: Do you still find challenges in your role?

LP: It’s getting better. Like I said, I’ve built good relationships with the guys on the floor so when there are problems, we usually try and work it through together.

We obviously have challenges with [not having] enough money to fix things. We’re an older mill, and we’re getting to the point where things just need to be replaced and repaired. We’re trying to work through how we can temporarily repair [things] until we can rebuild.

PPC: You’ve been in the industry for 13 years. How have you seen it change?

LP: I’m originally from Northern Ontario and, you know, there’s not very many mills running there anymore. So it’s become a smaller industry.

We have a good product here, so we’ve been lucky to keep running. We had the Tolko sale to AIAC and we did really well afterwards. We just worked really hard together.

PPC: What advice would you give to young person, especially a female, who’s thinking about a career in pulp and paper?

LP: I would say “work hard” is the main thing. Try to establish relationships with other people, especially those who can teach you a lot and can help you learn more about the industry and more about what career path you might want to follow.

If you want to see improvements or changes, then you have to think about how you can contribute in the most effective way possible to make the place better. Or make sure that you learn as much as you can and take all the opportunities. If there are training courses, take them. Canadian Kraft encourages [staff] to further our education and to develop our skills.

So always take that opportunity to do that even if you’re not quite sure. If the opportunity comes and you take the chance, maybe you’ll like it – and that might open a new door for you to something you never knew you’d like. I didn’t think 13 years ago I’d be a welding inspector but it’s something I really enjoy now that I’ve had the exposure to it.

Work hard, keep a positive attitude, continue to educate yourself, challenge yourself, and share your knowledge with those around you.

This interview has been condensed and edited for clarity.

_____

This post is part of CFI, Pulp & Paper Canada and Canadian Biomass’ Women in Forestry project celebrating International Women’s Day on March 8. Find more content here and follow on social media with the hashtag #WomeninForestry, as well as #IWD2020 and #EachforEqual.

Print this page