Features

Energy Management

Environment & Sustainability

Forestry

Paper

Pulp

Energy and emissions landscape of the forest sector

A comparative analysis of fossil fuel and bioenergy emissions in key parts of the forest value chain.

August 21, 2023 By Luciana Savulescu (corresponding author), Jawad Jeaidi, Adam Rogerson, Bruno Gagnon and Serge Bédard

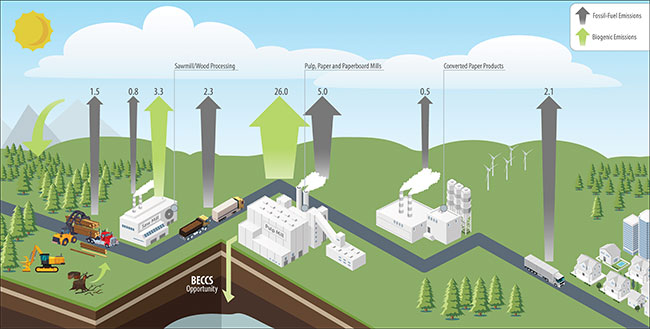

Figure 2: Emissions Overview Across Forest Value Chain (data in Mt CO2 equivalent units)

Image: NRCan

Figure 2: Emissions Overview Across Forest Value Chain (data in Mt CO2 equivalent units)

Image: NRCan Canada’s Net-Zero by 2050 commitment will require comprehensive action across all industrial sectors to curb greenhouse gas (GHG) emissions. The Canadian forest sector took early actions in this direction, successfully reducing its GHG emissions by nearly 70 percent since the early 1990s. Achieving this milestone has involved enhancing energy efficiency and transitioning from fossil fuels to bioenergy by utilizing wood processing residues. Additional efforts are now needed to effectively meet Canada’s GHG reduction targets. While it is technically feasible to fully realize the potential of the forest sector to reach net-zero, or even net-negative emissions, substantial investments in technical and capital resources are indispensable to implement cutting-edge energy-efficient technologies, electrification, bioenergy and carbon capture.

Context

With energy consumption of approximately 600 PJ/year, the manufacturing facilities of the forest sector use more energy than any other major Canadian manufacturing sector, including the iron and steel, cement, oil refineries and petrochemical sectors. However, this sector is unique in that a large part of its energy needs is met by renewable energy. Biomass-based fuels have enabled the industry to reduce its reliance on fossil fuels, helping to lower its net GHG emissions considerably.

Energy assessment and mapping

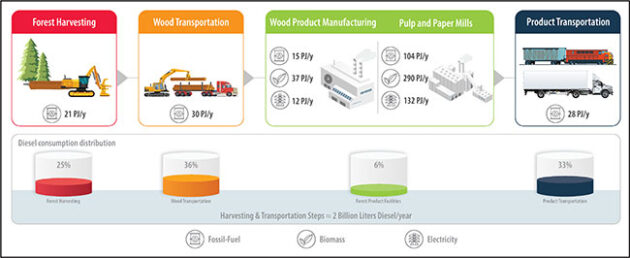

Evaluation of fuel consumption across major steps of the forest sector, from forest harvesting to transportation of finished products (Figure 1), has been performed to define the energy profile of the Canadian forest value chain. Data on energy usage and GHG emissions are available through public databases such as the National Energy Use Database launched by Natural Resources Canada in 1991, Canada’s National Inventory Report, and GHG Reporting Program led by Environment and Climate Change Canada. Since these databases focus on energy and GHG data for the pulp and paper sector, information for upstream and downstream operations is less defined. Specific attention was given to estimating diesel consumption.

The results illustrate that energy sources – fossil fuels, bioenergy, electricity – are not equally distributed along the forest value chain. Most of the energy is consumed in wood product manufacturing and pulp and paper mills (20 percent of the energy from fossil fuels, 25 percent as electricity and 55 percent from bioenergy). Mills also produce 8950 GWh per year of renewable electricity, of which over 60 percent is coming from cogeneration. Diesel fuel is used for harvesting operations and transportation of logs and wood chips to pulp mills, and shipping final products carried out by truck or rail transport.

Natural gas is the most common fossil fuel in manufacturing facilities, mostly supplied to boilers, lime kilns and internal combustion dryers. Diesel consumption, on the other hand, in sawmills, wood product manufacturing, forest harvesting, wood and product transportation is estimated to be approximately 80 PJ/y or 2.1 BL/y of diesel. Diesel in these processes is used in heavy machinery and is heavily impacted by carbon policies such as Clean Fuel Regulations and the carbon fuel charge.

Figure 1: Energy Consumption Across Forest Value Chain

Image: NRCan

Emissions landscape

GHGs emitted from fossil fuels are generally considered to be the primary driver of anthropogenic climate change and are the focus of most carbon reduction policies. Emissions from biogenic sources, however, are considered carbon neutral within the accounting standard put forward by the International Panel on Climate Change. When biomass comes from residual materials generated by sustainable forestry, the biogenic emissions released from its combustion are offset by CO2 captured by forests, with a carbon debt. In that framework, long-term storage of biogenic CO2 is considered a negative emission.

The distribution of energy sources translates to a similar distribution of carbon dioxide equivalent (CO2e) emissions generated along the forest value chain. In 2020, 10.1 million tonnes (Mt) of fossil fuel-based GHG emissions were produced (excluding final product transportation), with around 54 percent (5.5 Mt CO2e) originating from stationary sources within pulp and paper facilities. The production of fossil emissions from stationary equipment is as follows: the power boilers account for about 71percent of fossil fuel emissions (including co-firing in hog fuel boilers), the lime kilns contribute approximately 20 percent and tissue/BCTMP dryers at nine percent. While fossil-based emissions through the forest value chain (Figure 2) are notable, they pale in comparison to the biogenic emissions, which amounted to 29.3 Mt CO2e, bringing the sector’s total emissions to approximately 39.4 Mt CO2e when final product transportation is excluded.

The forest sector’s emissions are mostly biogenic and largely concentrated in pulp and paper mills. The biogenic CO2 is emitted from residual pulping liquor burned in recovery boilers in the kraft pulping process (57 percent), from wood-based residues in power boilers (40 percent) and from process emissions in lime kilns (three percent). The wood processing facilities also use a large amount of bioenergy, mostly in boilers, furnaces and dryers. Capturing part of these emissions, especially in kraft mills, and permanently removing them from the atmosphere, would enable the forest sector to become carbon-negative. This could help Canada achieve net-zero industrial emissions by compensating for hard-to-abate industrial sectors. Additionally, it presents a valuable revenue stream for the pulp and paper industry. Carbon capture from pulp mills has been shown to be feasible but is not currently economically viable at a small scale if no credit is provided for negative emissions or without a market to sell captured CO2. While biogenic emissions are usually reported, they are not priced or subject to regulation under current national carbon policies.

Why must we act now?

- In its 2030 Emissions Reduction Plan, Canada has committed to exploring the potential for negative-emission technologies in the forest sector, particularly in facilities where biomass is used as an energy source.

- Carbon taxes can be mitigated by lowering GHG emissions at forest products facilities.

- Cost-effective energy efficiency measures are still available if manufacturing facilities to further reduce fossil-fuel utilization, notably using heat recovery systems and advanced controls.

- Increasing carbon prices will likely help improve the collection and utilization of harvesting residues.

- Industry transformation is ongoing as traditional products such as paper and newsprint give way to different new products.

Key takeaway

Canada’s forestry sector is a large and energy-intensive industry, occupying a unique position as a predominant consumer of bioenergy. This sector offers promising avenues for reducing fossil fuel consumption and attaining carbon negativity. By integrating additional decarbonization strategies such as enhancing energy efficiency, transitioning to electrification and bioenergy, and implementing carbon capture technologies, the forestry sector can not only thrive but also shape a sustainable, low-carbon future for Canada.

© His Majesty the King in Right of Canada, as represented by the Minister of Natural Resources, 2023

Luciana Savulescu (corresponding author), Jawad Jeaidi, Adam Rogerson are from Natural Resources Canada, CanmetENERGY, Industrial System Optimization Group. Bruno Gagnon is from Natural Resources Canada, Canadian Forest Service, Trade, Economics & Industry Branch.

Print this page