News

Press Felt Centering With UltraEdge Improves Press Operation

February 1, 2010 By Pulp & Paper Canada

UltraEdge is Metso’s new non-contacting fabric edge tracking solution, providing precision and reliability in fabric control on paper and board machines. Problems with fabric control have direct finan…

UltraEdge is Metso’s new non-contacting fabric edge tracking solution, providing precision and reliability in fabric control on paper and board machines. Problems with fabric control have direct financial effects, such as loss of felts or dryer fabrics and machine downtime needed to replace them.

UltraEdge provides accurate felt width and shrinkage behavior information during production. When UltraEdge units are installed on both the tending and drive side of the machine, the felt width data can be obtained and the felt can be centered automatically. Centering the felt typically improves runnability in the edge areas due to symmetric felt wear. Start-ups get faster, which improves machine efficiency. UltraEdge is an excellent tool for troubleshooting the root cause of problems thanks to the felt width data and accurate felt edge positioning in connection with felt damage, for example.

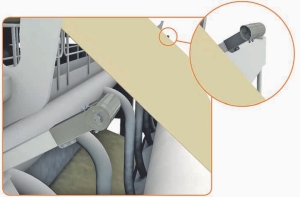

The operation of UltraEdge is based on ultrasound technology, which eliminates all tracking-related abrasion and wear at the fabric edges. The sensor transmits high-frequency ultrasonic sound bursts, with which the distance of the fabric edge from the sensor can be calculated. Compared to other optical fabric positioning solutions, fabric color and composition have no effect on measurement.

UltraEdge is designed for both press and dryer section fabric control on all paper and board machines. It can be used for edge tracking with both pneumatic and electromechanical guides. The dryer section application is designed for the challenging dryer hood conditions.

Metso 514-335-5426,

Print this page