Products

Test & Measurement

ABB launches digital solution for optimizing winder performance

July 26, 2019 By P&PC Staff

July 26, 2019 – ABB has introduced Winder Performance Optimization, a digital solution for papermakers seeking to maximize asset performance, convert to different paper grades and/or increase machine speed, without replacing existing winders.

The new solution works by benchmarking winder performance, implementing improvements, monitoring to sustain performance and applying online calculations that continuously adjust winder acceleration and deceleration targets. The company says this optimization aligns capacity to demands and can improve productivity significantly – recent implementations have provided eight per cent improvement.

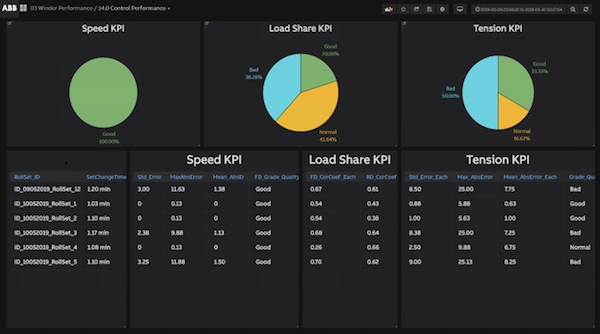

KPIs are continuously monitored and analyzed to enable preventive maintenance and increased uptime. In regenerative mode, the solution feeds energy back into the system while decelerating winder drives, enabling mills to be more energy efficient.

ABB’s Winder Performance Optimization includes the ability to monitor and improve roll set quality, and improved use of machine reel capacity. Local and remote dashboards enable instant data visualization, with advanced analytics and daily analysis of performance, control (speed, load share, tension) and roll set performance carried out by ABB experts.

Customers can also receive configurable alerts to highlight performance falling outside site-specific thresholds.

ABB Winder Performance Optimization is part of the ABB Ability Performance Optimization solution suite, whose offerings focus on maximizing equipment and process performance to ensure efficient operations.

Print this page