News

Products

Equipment & Systems

Maintenance & Reliability

Valmet introduces monitoring application for bearing lubrication in fibre processing equipment

October 12, 2023 By Sukanya Ray Ghosh

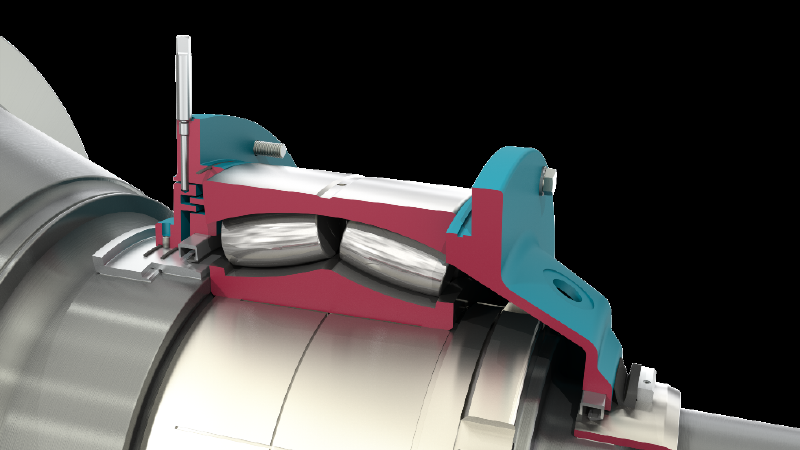

Photo: Valmet

Photo: Valmet Valmet has launched a new application, Valmet Oil Monitoring, to remotely monitor oil lubrication in fibre processing equipment.

As various rotating machinery throughout the fibre line perform under extremely harsh and demanding environments, it is often difficult to manually retrieve oil samples. Maintaining adequate surveillance of lubrication properties against harmful effects can prove very challenging, notes Valmet in a press statement.

With Valmet Oil Monitoring, upcoming failures can reportedly be foreseen through changes in lubrication oil quality. The solution enables corrective actions before the actual failure arises.

The Valmet Oil Monitoring application was first installed to follow roll bearings’ oil lubrication in a TwinRoll wash press in a European pulp mill. The application detected contamination in the bearing oil circulation unit. This observation was flagged, and the machine operators were able to react quickly with corresponding maintenance actions, says Valmet.

Valmet Oil Monitoring, together with the specific applications for chip feeders in continuous cooking and TwinRoll presses in pulp washing, form the offering of Valmet’s modular reliability monitoring platform. The platform is intended for fibre processing equipment and was introduced in 2022.

Valmet’s reliability monitoring applications are part of the Valmet Industrial Internet offering.

Print this page