News

Products

Equipment & Systems

Maintenance & Reliability

Voith announces release of a new design of its OnQ FormingSens

September 19, 2022 By P&PC Staff

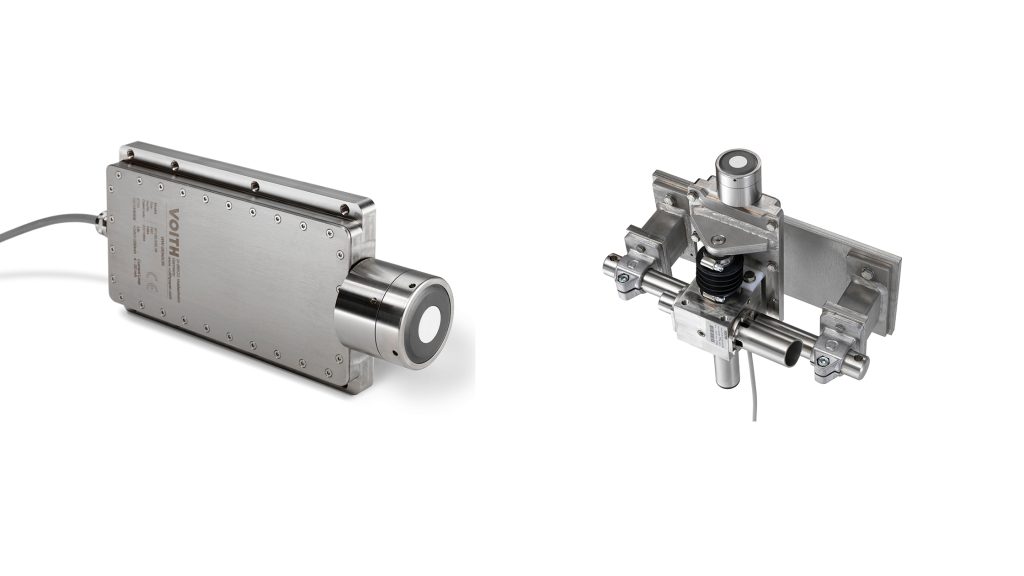

The focus of the new design is on a reliable, low-vibration construction, as well as a simplified electrical design. (Photo: Voith)

The focus of the new design is on a reliable, low-vibration construction, as well as a simplified electrical design. (Photo: Voith) The new design of Voith’s OnQ FormingSens focuses on solid, low-vibration construction, as well as a simplified electrical design. Voith’s experts reworked the mechanical mount so that the operator can now fine-tune the penetration depth from outside the machine via waterproof mechanical gear. The sensor holder can be flexibly positioned on various existing dewatering elements in the former.

The permanently installed application is designed for higher safety as no direct contact of the operator with the forming fabrics is necessary. Improved sensor housing ensures higher long-term stability. The new generation OnQ FormingSens is installed to a nearby terminal box. It can be serviced by Voith experts via a service connection. This allows the solution to be better connected to customers’ existing infrastructures, such as the process control system.

OnQ FormingSens is used by paper manufacturers of different grades. With microwave technology, the solution measures fluctuations in water weight in real time. Papermakers can use this information to systematically improve their settings, achieve a stable dry content at the end of the forming section and utilize the maximum dewatering capacity in the press section. For maximum user-friendliness and reliability, Voith experts have now further optimized the design of the solution.

Based on the measurements of OnQ FormingSens, the control loop can be closed with the fully automatic dewatering control OnC.Dewatering. The control system defines and stabilizes the dry content of each layer produced and thus increases ply bond on multi-ply machines.

Print this page