News

Products

Operations & Management

Paper

Process Control

Voith introduces new edge trim concept EdgeSaver for paper manufacturers

January 31, 2022 By P&PC Staff

Image: Voith

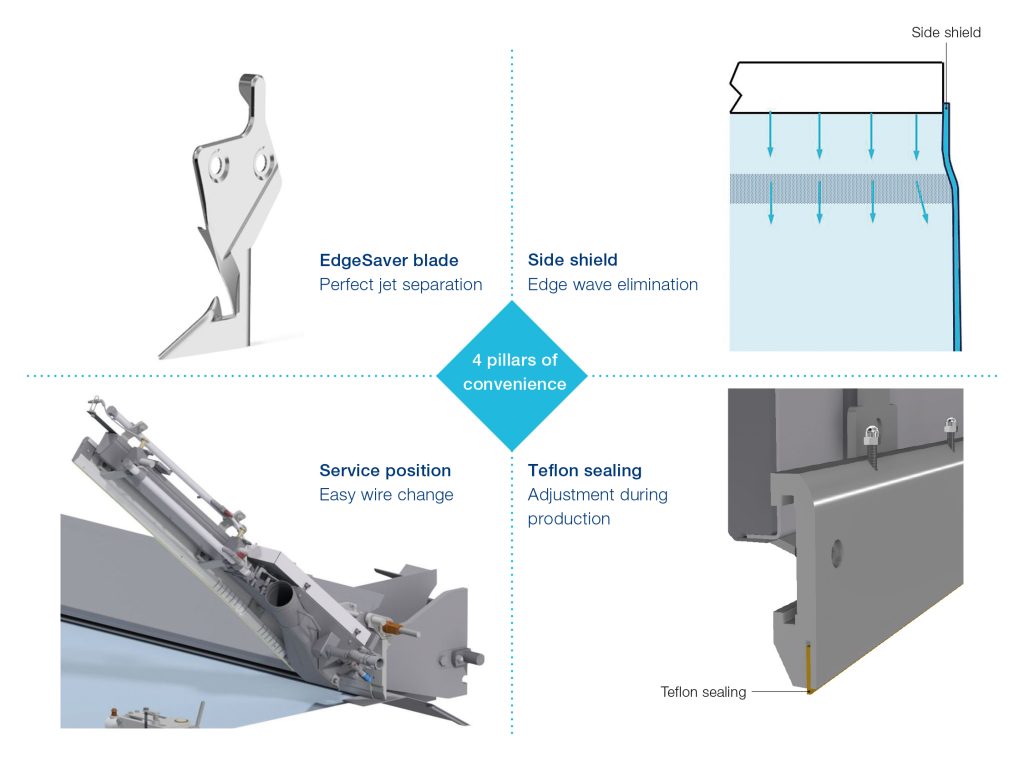

Image: Voith Voith has introduced its new edge trim concept – EdgeSaver – a system designed to trim the web edge in the stock jet exiting the headbox.

Voith noted in a release that with the EdgeSaver, paper manufacturers will save valuable raw materials like virgin fibres, as well reduce the energy consumption for paper production.

The design of the EdgeSaver blade offers an energy-efficient solution for adjusting the web edge directly in the headbox jet. Fibres that exceed the required paper web width are not lost in the couch pit, as they are discharged before the suspension reaches the wire. The discharged stock suspension can be returned directly to the primary fibre stock cycle in a single-sort process.

In addition, the web width can be adjusted to specific customer requirements in the wet end, which offers crucial advantages, especially when producing various paper grades with different run-out widths.

The EdgeSaver’s specially manufactured side shield with a patented, adjustable S-shape aids in minimizing edge waves. This facilitates the successful threading of the web into the press section. The Teflon seal on the underside of the side shield provides an optimal seal to the wire. The seal can be adjusted with the machine running.

Voith states that the EdgeSaver can be mounted to the standard headboxes of all manufacturers. It can be installed on both sides of the web in a few hours during a shutdown.

Print this page